Resin Conveying

Medical Molder Boasts Showpiece Material-Handling System

Flex Manchester is so proud of its new, elaborate drying/conveying system that it greets visitors front and center on their way to view the cleanroom molding floor.

Read MorePaving the Road to a Circular Economy

Sustainability and circular economy aren’t buzz words. They are and will continue to be the way of doing business for processors.

Read MoreWhich Self-Contained Plastic Vacuum Loader is Best?

For conveying resin materials over short distances there’s no more efficient and versatile way than using a self-contained vacuum loader. It may seem like a basic piece of equipment but selecting the right model can make a big difference in efficiency, process consistency, and reduced changeover time.

WatchFlexicon Expands at World HQ

Increase in space aimed at meeting increased demand bulk- handling equipment and systems.

Read MorePlug-and-Play Conveying System

Convey from handfuls to 3500 lb/hr of powders, pellets, flakes, fibers, wood flour, pigments, and more.

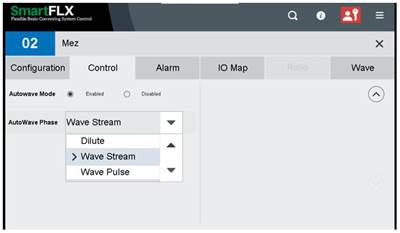

Read MoreSystem Protects Resin from High-Speed Conveying

Processors can easily and automatically select and use capabilities to protect resins from damage caused by dilute-phase conveying systems operating at excessive speeds.

Read MoreBag-Dump Module for Mixers, Blenders, More

Designed to contain dust generated when bulk materials are dumped manually.

Read MoreFlexible Screw Conveyor Resists Abrasion

Features steel conveyor tube, heavy-duty flexible screw, and heavy-gauge floor hopper and discharge housing.

Read MorePre-Engineered Vs. Custom Vacuum Conveying Systems for Compounding and Extrusion

When it comes to vacuum conveying systems for plastics processing, custom powder handling solutions are not always required. Pre-engineered, turnkey solutions can be a perfect option for powders and bulk solids in a wide range of industries.

Watch