Resin Conveying

Loaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

Read MoreCompact, Mobile Dryer Has Unique Conveying Capabilities

NPE2024: Mobile dryer includes closed-loop conveying to minimize the use of ambient air for resin movement.

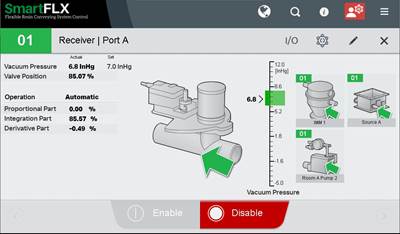

Read MoreConveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreRadar Level Sensor Streamlines Bulk Material Inventory Management

NPE2024: The NCR-86 is designed to ensure rapid data updates, enhancing efficiency in inventory management.

Read MoreBulk-Bag Filler Equipped with Pallet Dispenser

Between 14-16 pallets can be loaded for staging into the pallet dispenser.

Read MoreHigh-Capacity Bulk Bag Discharger Can Be Moved Around

Equipped with a flexible screw conveyor, unit enables rapid, dust-free discharging and conveying of bulk solid materials at multiple plant locations.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Watch