Sheet Extrusion

How to Effectively Reduce Costs with Smart Auxiliaries Technology

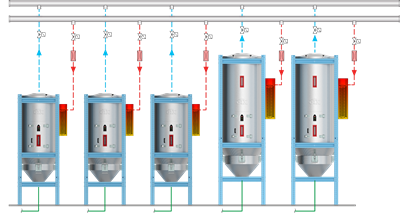

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

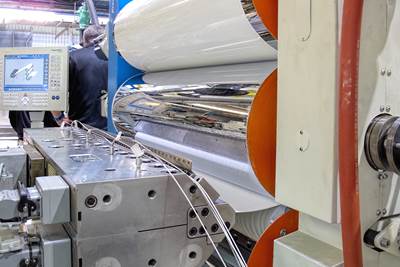

WatchRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreMacro Names Anzini Tech Sales Manages for Southeast

Has worked in technical roles for leading processing companies in his career of 40+ years.

Read MoreOMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

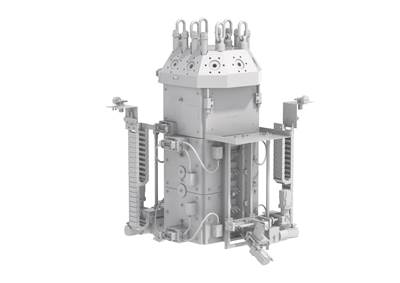

Read MoreDavis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

Read MoreDie-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

Read MoreDie-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreRoll Stand is Compact, Flexible

Features a unique, compact design for sheet processors with very limited production floor space.

Read More