Single-Screw Compounding

Solve Seven Common Pelletizing Problems

Here's a quick how-to on keeping your pelletizing line churning out quality product.

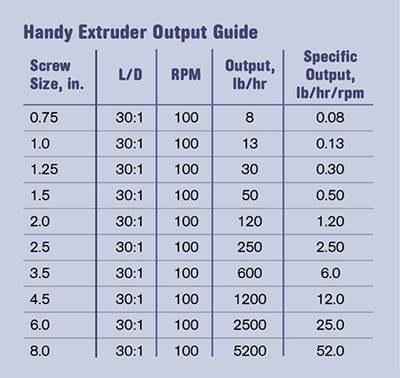

Read MoreGet Smarter on Extruder Sizes

Processors tend to recommend a much larger extruder than what’s really necessary for the job and the capabilities of the downstream equipment.

Read MoreExtrusion & Compounding at NPE: Advances Push Efficiency Envelope

Blown film towers may have been scarce, but there was no shortage of new technology aimed at helping to make extrusion processors more profitable.

Read MoreHow to Spec’ Screws & Barrels For Running Corrosive Materials

Here’s a guide to specifying screws and barrels that will last under conditions that will chew up standard equipment.

Read MoreA Pioneer in ‘Clean Compounding’

When Plastics Color Corp., based in Calumet City, Ill., established a new compounding plant in Southern California, the firm decided this couldn’t be an ordinary color/additive masterbatch facility.

Read MoreOn Site: Tailoring Medical Solutions… Sometimes in 50-lb Lots

Smaller volumes teams with higher quality and value as keys to the success of this growing medical compounder.

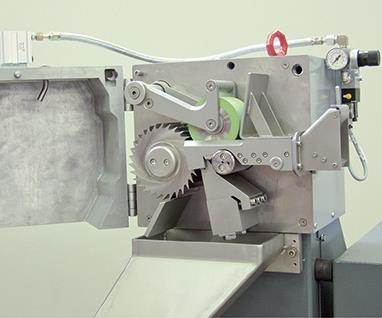

Read MoreFollow These Tips to Select the Right Pelletizer

Start by assessing the status quo, as well as defining future needs. Develop a five-year projection of materials and required capacities. Short-term solutions very often prove to be more expensive and less satisfactory after a period of time. Most of all, know your options.

Read MoreCompounding: New Torque Record Set At K '10

New twin from Coperion also pumps up output by 30%

Read MoreCompounding & Mixing at NPE 2003

Torque levels and output capacities of corotating twin-screw compounders coming to NPE are higher than ever.

Read MoreGently Does It

Unique R&D experience in urethane chemistry created a niche for New England Urethanes in North Haven, Conn., a small, highly specialized compounder serving medical-device manufacturers.

Read More