Thermoforming

Internal Benchmarking: Setting Targets

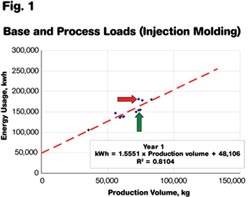

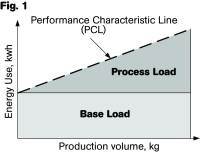

Last month, we discussed how to graph your plant’s “process energy fingerprint.” Now we’ll show you how to make use of that information.

Read MoreWhat’s Your Process Energy Fingerprint?

As we discussed in last month’s column, your plant’s “energy fingerprint” is composed of the base load and the process load.

Read MoreKnow Your Plant’s ‘Energy Fingerprint’

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreRobots Manage Logistics For Entire Packaging Plant

Inventory management may be too important to be left to people.

Read MorePlastic Pallets Gain Ground In an Eco-Conscious World

Low-cost wood is still king, but plastics’ reusability is a growing attraction among manufacturers looking for sustainable material-handling options. The one major hurdle is today’s high resin prices.

Read MoreInvesting in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

Read MorePlug-Assist Coating Improves Surface Quality and Formability

Manufacturers and users of plug-assist tooling have a new technique to improve the surface finish and cycle time of thermoformed parts.

Read MoreBlow Molders and Thermoformers Try Plastic Rapid Tooling

Rapid prototyping (RP) equipment is increasingly being used to manufacture prototype and short-run production molds for blow molded and thermoformed parts.

Read MoreCoatings Give Aluminum Molds Cost/Performance Edge Over Steel

New cost-effective technologies are designed to make aluminum an attractive alternative to tool steels in a range of plastics molding processes. One method uses a plasma technique to convert the aluminum surface into a hard, dense, wear-resistant ceramic. Another approach uses electro-deposition to apply a surface coating with high hardness, corrosion resistance, and chemical resistance.

Read More