Thermoforming

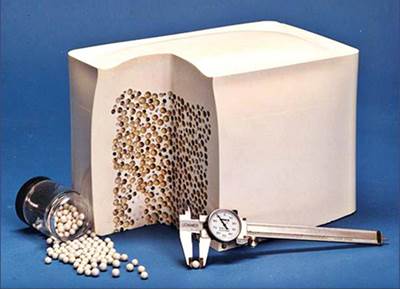

Optimize Cut-Sheet Forming With Syntactic Foam Plug Assist

Common problems encountered in the cut-sheet thermoforming process include thin spots, webbing, poor part definition, and plug/pusher mark-off.

Read MoreThermoforming at NPE: Machines Raise Performance Bar

Exhibitors at this year’s show introduced an assortment of new machines and upgraded models with designs incorporating the latest in mechanical, hydraulic, and electronic technologies.

Read MorePE/PS Interpolymer Modifies Polyolefins To Process Faster, Thinner, Better

Novel hybrid of polyethylene and polystyrene acts as a processing aid for HDPE, LDPE, and PP.

Read MoreThermoforming at NPE: Less Scrap, More Power For the Buck

Most of the developments will focus on in-line systems.

Read MoreComposites Fabricator Chooses Thermoforming for Bus Part

Amtech LLC considers itself a composite specialist and engages in thermoset resin transfer molding and vacuum-assist RTM, plus finishing, assembly, and custom packaging from a 220,000 ft² plant in Wapato, Wash.

Read More‘Back to Basics’ Fuels More Innovation at Thin-Gauge Former

Shift from private to capital ownership give Tray-Pak a boost.

Read MoreSustainability Will Change Your Business

Do you have a sustainability officer yet? You might need one. It's probably even more likely that your customers have one, and you will have to pay attention to them if you want to continue to supply them with plastic parts or products.

Read MoreOn Site: Evolution of a One-Stop High-Tech Thermoformer

A company that started as a toolmaker has evolved into a thermoforming solutions provider

Read MorePhysically Foamed HIPS Is New Factor in Rigid Packaging

Relief for escalating costs of packaging materials and an opportunity to address sustainability goals are two factors that have helped attract global attention to a new physical foaming technology for HIPS packaging.

Read More'Green'...And Microwaveable Too

New technology from Teknor Apex Co., Pawtucket, R.I., eliminates a property tradeoff that could allow polylactic acid (PLA) to supplant polystyrene and polypropylene for microwavable frozen-food trays, lids for hot beverage cups, and carry-out containers.

Read More