Tooling

Why Put Flow Simulation on an Injection Machine?

This emerging technology sounds promising, but its practical benefits have yet to be demonstrated clearly.

Read MoreThe Accidental Molder

Peyton Owen came to plastics after decades in commercial real estate, but by empowering his employees through listening, he’s learning molding and success at D&M Plastics.

Read MoreScared Straight on Molding Simulation

Molding simulation is such a vital technology today that many molders couldn’t imagine life without it. But as a “consumer” of such a service, you have to know how to carefully critique the simulation results, which can hide a multitude of shortcuts and compromises that threaten their utility.

Read MoreBarnes Opens Customer Technology Center in Germany

Located within portfolio company Foboha’s Haslach facility, the center features an Engel injection machine, Foboha tools and leading technology from other Barnes Group businesses, including Synventive, Gammaflux and Priamus.

Read MoreFakuma: Metal Powder for Additive Manufacturing, Hot Runner Controls Among Show Intros

Hasco will unveil numerous new developments and additions to existing products, together with user-friendly tools, CAD features and digital services at Fakuma.

Read MoreFull Line of Hardened Ejector Pins

Suited for molding with high-glass-content resins, Regal’s Thru-Tuff Ejector Pins are made from M-2 high speed steel.

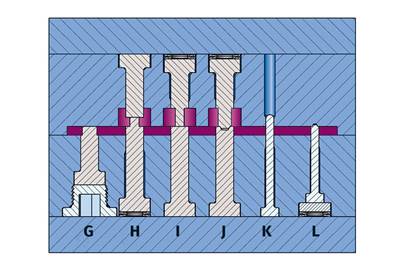

Read MoreHow to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

Read MoreWestminster Tool Wins 2021 Leadtime Leader Award

The Plainfield, Conn. moldmaker earned the Moldmaking Technology magazine award, which has been bestowed since 2003 to toolmakers that go above and beyond fast lead times and excel in all aspects of the trade.

Read MoreAdvanced Technology Empowers Hot Shots Entry

Magor Mold utilized Husky's Ultrashot technology to enable the molding of an ultra-thin PC medical diagnostic array.

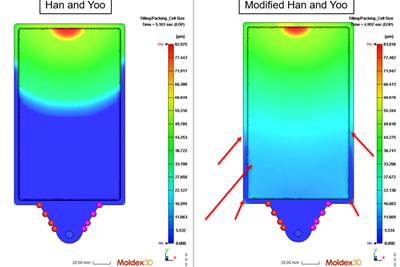

WatchFoam Molding Simulation Gains Better Bubble-Shrinkage Prediction

Microcellular foam molding simulation improves prediction of cell size and distribution in thin sections, core-back processes.

Read More