Injection Molding

In injection molding, material is fed through a hopper into a barrel where a reciprocating screw mixes and melts the material then injects it into a mold.

Narrow Your Injection Molding Search

ESSENTIAL READING

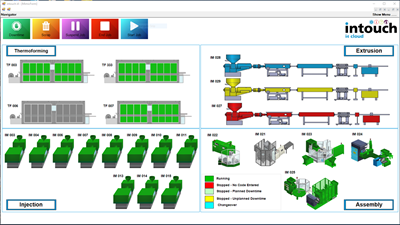

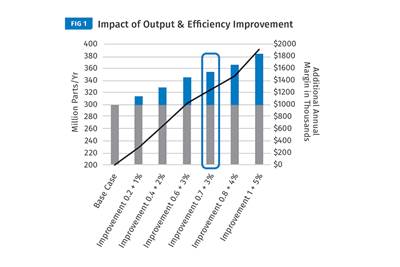

VIEW ALLProcess Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

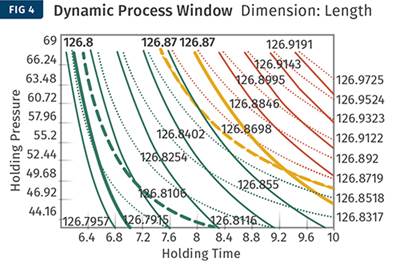

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

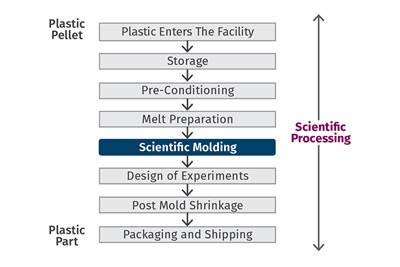

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreLatest Injection Molding News And Updates

Amcor, Berry Merge in All-Stock Deal

Move unites two complementary businesses to create a global leader in consumer packaging.

Read MoreCompact Solution for Two-Component Molding

Zahoransky’s new internal mold handling technology foregoes the time, space and money required for core-back, rotary table or index plate technologies for 2K molding.

Read MoreInjection Molded Parts Competition Now Accepting Entries

Plastics Technology’s Hot Shots parts competition is accepting submissions for the 2025 contest, with winners to be announced at PTXPO 2025.

Read MoreYizumi Opens Expanded Facility in Ohio

The Chinese supplier of processing machinery, including injection molding machines, unveiled a new expansion that nearly doubles its total footprint in Iberia to 44,000 square feet.

Read MoreEther-Based TPUs for Broad Range of Industry Applications

BASF’s Elastollan 1400 TPU series can be used for applications ranging from railway pads, hoses and profiles to show soles.

Read MoreAll-Electric Injection Molding Machine Line Expands

Fakuma 2024: Engel unveils new e-mac 500 with “High” clamping drive and encapsulated toggle-lever mechanism.

Read MoreFeatured Posts

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

Read MoreAMRs and Cobots Target Inspection, Palletizing and Movement of Finished Goods

The same year it marked its 70th year in business, custom injection molder Hoffer Plastics (South Elgin, Illinois) — which routinely reinvests more than 10% of its annual revenue back into new equipment — prioritized automation in that CapEx with some stunning results.

Read MoreInjection Molded Enclosures Plug into Potential Electric Vehicle Battery Applications

In partnership with material suppliers, Engel is proving out injection molded thermoplastic-based concepts for electric vehicle battery housings, utilizing production tools and dedicated machines at its large press factory in St. Valentin, Austria.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreImportant Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

Read MoreFAQ: Injection Molding

Plastic injection molding is a cyclical manufacturing process that allows for cost-efficient production of a mass number of identical parts made from either thermoplastic or thermoset materials.

Cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. A consistent cushion will create consistent part dimensions.

It is important to determine which type of bubble your part has, and what the root cause might be. Determining bubble type will allow you to pinpoint the source and determine your next course of action to eliminate the problem.

Most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention.

Injection Molding Supplier Categories

- Thermoformers

- Injection Molding Machines

- Platens

- Thermoforming Molds

- Extrusion Blow Molding Machines

- Pre-expanders, Polystyrene Bead

- Trimmers, Deflashers for Blow Molding

- Stretch-Blow Molding Machines

- Nonferrous Metals for Molds

- Mold/Die Management Systems

- Injection Molds

- Mold Steels

- Injection Blow Molding Machines

- Dip-Blow or Compression-blow Molding Machines

- Cutting, Stamping, Trimming Dies

- Quick-mold-change Equipment

- Mold Making and Repair Equipment

- Injection Molding Nozzles

- Parison Programmers

- Mold Components

- Injection Blow Molds

- Presses, Polystyrene Bead

- Spray Coating Systems (for Bottles)

- Rotational Molds

- Inserts

- Accumulators (Melt)

- Structural Foam Machines (for Thermoplastics)

- Injection Molding Non-return Valves

- Mold Evacuation Systems

- Mold Grease

- Rotational Molding Machines

- Compression/Transfer Molds

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Hot Runner Components

- Foam Molds

- Compression/Transfer Presses

- Prototype Molds