All-Electric and Hybrid Presses Hum at Osaka Plastics Show

The latest developments in all-electric and hybrid injection molding machines from several Japanese OEMs made their debut at Platex Osaka, a triennial show held in April in Osaka, Japan.

The latest developments in all-electric and hybrid injection molding machines from several Japanese OEMs made their debut at Platex Osaka, a triennial show held in April in Osaka, Japan. New models, improved clamping and injection systems, and enhanced controls were unveiled.

Lots of new features

Several new developments in the Elject NEX series of all-electric machines were displayed by Nissei Plastic Industrial Co. Among them were a new smaller press size, a new clamping technology, im proved mold protection, a new ball-screw lubrication system, and enhanced controls.

The new size is the 16.5-ton model NEX 150, developed for ultra-precision micro parts such as shutters for digital cameras, lens holders for cell phones, or fine-pitch connectors. It provides shot weights from 0.1 to 5 g of materials such as LCP, PPS, or nylons. The new model offers a choice of a standard belt drive that delivers 330 mm/sec injection speed or optional center-drive mechanism that injects at 500 mm/sec.

At the show, the NEX 150 demonstrated a new mold-protection system. A 16-cavity tool produced tiny LCP rings weighing 0.0028 g apiece on a 5-sec cycle. An infrared mold-monitoring system, immune to interference by ambient light, checked for parts remaining in the mold. This feature was combined with a new “ultra-high-speed reaction” system that instantly halts and reverses clamp motion to prevent mold damage.

To provide the ultra-precision control needed for micromolding (as well as more sensitive mold protection), Nissei speeded up the scan time of its TACT controller five-fold to 100 microsec. It stores up to 300 mold programs, and the operator interface now has a larger, 12-in. color LCD touchscreen.

For larger models, Nissei introduced a closed-loop oil lubrication system that eliminates use of grease on the injection ballscrew and reportedly improves ballscrew life and precision of injection movement in fast-cycle molding. (In addition, the ballscrews themselves have been redesigned for 2.5 times longer life.)

The Liquid Lubrication system was shown on a 198-ton NEX 4000. Lubricating oil is delivered from a separate tank underneath the press by a pump and flowmeter to an enclosed section of the ballscrew. A return system catches excess oil from the screw and transports it back to tank.

This system reportedly provides more reliable, continuous lubrication of the injection ballscrew. Conventional grease can solidify and lubricate unevenly, leading to scratched bearings. Grease can also splatter, making it a potential contamination problem, says Nissei. Nissei also introduced the Flat Clamp, a means of reducing platen deflection and applying more uniform clamp force in fast-cycle precision molding. The new five-point toggle mechanism was shown on a 22-ton press. The toggle pins and all other moving parts were redesigned for higher rigidity and abrasion resistance, while, the stationary side of the press has a new center support system. The redesign is also said to cut dry-cycle take out times by 35%.

In addition, Nissei’s new automatic clamp-force correction circuit for its NEX presses adjusts tonnage throughout the cycle. It enables so-called “weld-less” injection/compression molding, which was demonstrated in molding a cell-phone keypad plate with numerous holes in a two-cavity mold on an 88-ton NEX 1000 press.

Faster control response

Toyo Machinery & Metal Co. (represented here by Maruka) rolled out a new generation of its all-electric machines. The Si-III is offered in 11 sizes from 33 to 750 tons. An 850-tonner is being considered. The machines have a new PLCS 11 “network servo” control system that reportedly provides 50% faster response than before. Injection acceleration from zero to maximum speed takes 32 millisec and deceleration takes 27 millisec. The new design also reduces energy use a further 3%. Controller scan time is reduced to 100 microsec. This fast response suits the machines to high-precision and thin-wall molding, according to Toyo.

Also new is a temperature-control system said to be 20% to 50% more accurate than before. It holds fluctuations to ±2°C all along the screw, including the rear barrel zone, so as to keep material metering time constant.

In addition, Toyo’s new SRC-II metering technology uses the screw to compress the melt immediately after metering so that melt density is uniform throughout the shot before injection starts. A new optional SRC-III metering system locks the check ring immediately upon completion of plastication to prevent melt backflow. And the “soft-touch” two-step deceleration of the nozzle-touch ball screw is said to reduce impact on the nozzle and mold.

Hybrid models extended

Meiki Co. Ltd. rolled out an updated version of its Nadem line with electric/hydraulic hybrid clamp. The new Nadem 1500II DM is a 165-ton model featuring a 60% thicker stationary platen that reduces deflection.

Though not shown in Osaka, Mitsubishi Heavy Industries Ltd. (represented here by MHI Injection Molding Machinery) extended the range of its Em line of hybrid presses with a new 1600-tonner. (This model was exhibited at the Plast-Ex show in Toronto last month.) Like the other models in the range, clamp movements are accomplished by a servo-driven central ballscrew. A split-nut system engages the tiebar for lockup, then an electric inverter motor operates a hydraulic system to generate clamp force on the four tiebars. The 1600-tonner has a tiebar clearance of about 73 x 60 in. and can fit a maximum mold size around 98.5 x 59.5 in. Additional 2200-, 2800-, and 3300-ton models are being considered for the line, which currently ranges down to 720 tons.

Related Content

All-Electric Injection Molding Machine Line Expands

Fakuma 2024: Engel unveils new e-mac 500 with “High” clamping drive and encapsulated toggle-lever mechanism.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

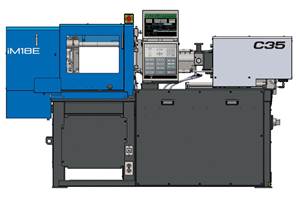

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More