Share

The “circular economy” loomed large during October’s K 2019 show in Düsseldorf, with just about all key suppliers of materials and additives showcasing their latest sustainability efforts.

The first PC resin based on certified renewable feedstock was launched by SABIC.

Our September show preview discussed the increasing number of upstream and downstream industry collaborations underway in chemical and mechanical recycling, biobased feedstocks, and new resins offered with recycled and biobased content. While a good portion of these efforts involve polyolefins, headway also is being made with other resins such as polystyrene, styrenic blends, and nylons, as previously reported. And, at the show, we saw the launch of the first renewable-feedstock polycarbonate (PC).

Also targeting sustainability, in perhaps a less direct way, are new high-performance engineered resins and composites for metal replacement that boast significant lightweighting. While this is of paramount importance in the automotive sector and increasingly targeted to the electrification of vehicles, it has a major impact in a host of other markets—packaging, building/construction, electrical/electronics (E/E), consumer goods, industrial components, and medical devices.

Also targeting sustainability are new high-performance engineered resins and composites for metal replacement that boast significant lightweighting.

Among the news unveiled at the show:

▪ SABIC launched the first PC based on certified renewable feedstock—60% of it is made from tall oil derived from pulp waste. The company considers this a major milestone in its strategic sustainability pathway as it has extended its offering beyond polyolefins, where the firm already has certified circular and certified renewable portfolios. SABIC’s PC cradle-to-gate life-cycle assessment (LCA) study reveals potentially significant reductions in carbon footprint (up to 50%) and fossil-fuel depletion (up to 35%) for production of its Lexan PC resin with renewable feedstock. (Note: “Cradle-to-gate” LCA considers the product’s life cycle only up to the completion of its manufacture.)

SABIC worked closely with the International Sustainability and Carbon Certification (ISCC) Association to provide proof of incorporation of renewable feedstock in its PC production and the resulting sustainability claims, verified by independent third-party auditors. In addition, CEPSA—the Spanish multinational oil and gas company—is a strategic value-chain partner in this project, supporting SABIC through production of renewable intermediates. The new PC will be produced initially at SABIC’s facility in Bergen op Zoom, The Netherlands, with global availability in the future. The certified PC resin may be used for applications in all market segments, including automotive, consumer, E/E, building/construction, and healthcare.

▪ Covestro showcased an impressive prototype of a vehicle of the future--a multifunctional, mobile living and working space. It integrates a seamless three-dimensional display—a large-format visual experience—made of high-optical-quality Makrolon PC and Makrofol PC film.

The seamless 3D display integrated in Covestro’s protopype vehicle is made of high-optical-quality Makrolon PC and PC film.

▪Solvay Specialty Polymers unveiled its new line of Xencor LFT (long-fiber thermoplastic) compounds along with the world’s first all-polymer e-bike, manufactured by Monaco-based Stajvelo. The company selected Solvay’s long-fiber Xencor polyarylamide (PARA) compound based on its ability to meet stringent structural, mechanical, and aesthetic requirements. Xencor PARA significantly extends the performance capabilities of Solvay’s Ixef PARA compounds (also known as MXD6 nylon), which have replaced metal in medical devices, automotive exteriors, and small appliances

Xencor LFT compounds typically contain 30% to 60% fiber reinforcement. They are suitable for semi-structural applications in markets such as automotive, advanced transportation, construction, industrial, and consumer, as well as sports and leisure.

The world’s first all-polymer e-bike is made of Solvay’s new Xencor LFT PARA.

▪ Solvay Engineering Polymers introduced its advanced Technyl Max nylon 66, which was chosen by France’s Carbody—an expert in safety and sealing solutions for the automotive industry—to develop the first all-plastic brake pedal. Called Skeleton, the pedal concept replaces conventional steel with a lightweight hybrid structure. Skeleton features a rod-shaped composite structure, which is over-molded with 60% glass-filled Technyl Max. This reportedly provides superior fracture resistance under loads up to 3000 N and maintains its operational safety even beyond that limit (the average force applied in emergency braking is said to be around 500 N).

Technyl Max is also targeted to semi-structural components such as transmission and motor-mount cross beams, air-shutter grilles, and seat structures. Its low density offers significant weight savings over typical die-cast metals at comparable tensile strength. This is important for applications in electric vehicles, which require even greater rigidity and fatigue resistance due to higher vibration frequencies.

Solvay’s new Technyl Max nylon 66 was chosen by Carbody for the Skeleton all-plastic brake pedal.

▪ ExxonMobil announced a collaboration to develop a new vibrant PP color spectrum to meet auto interior-design trends for next-generation vehicles. The company is developing new lightweight Exxtral PP compounds, such as BMU046x concept grade with 10% lower density than a commercial PP compound used for door panels. The Exxtral grades are said to be easily colored at the press with masterbatches. Collaboration with Clariant and with PVL, a part manufacturer and specialist in decoration and design, has led to a the new pallette of 23 vibrant colors.

▪ ExxonMobil also unveiled technology that entails blending its Exceed XP mLLDPE with its PP resins to deliver films that are said to have extraordinary mechanical performance and high-heat resistance. The new technology is said to push blown film boundaries to create new opportunities for high-temperature applications, such as heavy-duty sacks. Lower system costs are possible due to downgauging opportunities of up to 25%, compared with a standard 125-micron film. The new technology reportedly allows production of films with up to 50% higher dart-drop impact resistance, up to 40% better creep resistance—even at up to 70 C/158 F—and no film deformation due to shrinkage up to 140 C/284 F, compared with incumbent solutions using HDPE.

ExxonMobil unveiled technology that entails blending its Exceed XP mLLDPE with its PP resins to deliver films with extraordinary mechanical performance and high-heat resistance.

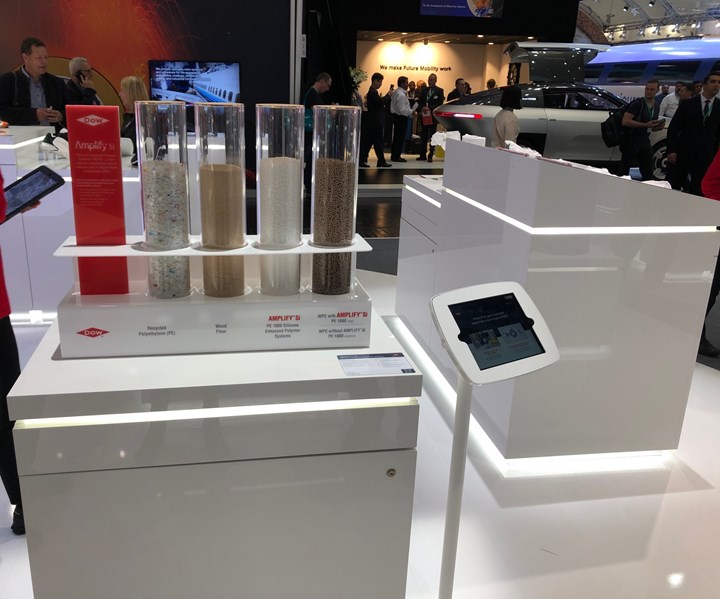

▪ Dow unveiled new Amplify Si PE—an innovative silicone-enhanced PE processing and performance additive for wood-plastic composites. Extensively field tested in North America, it has been shown to allow for 100% recycle content of not only HDPE but also LLDPE. At low loading levels of 2-7%, it has been shown to allow for wood-flour content of up to 60% vs. the typical 35-40%, and to enable lower melt temperatures and lower extrusion torque. Decking boards made with it reportedly boast 30% higher mechanical properties over boards using other processing additives. Water repellency is also claimed and Dow experts believe that its higher performance will allow for thinwalling and a drastic reduction in reject rates, which reportedly are now in a range of 8% to 15% in this market.

Dow’s Amplify Si PE silicone-enhanced PE performance additive for wood-plastic composites allows for up to 100% recycle content.

▪ Lanxess announced that it is breaking ground in deploying artificial intelligence (AI) in development of customized high-performance plastics, through its collaboration with AI company Citrine Informatics, Redwood City, Calif. Glass-fiber sizing is a major area of focus to allow customization and reduce time to market.

The goal is to optimize bonding of the glass-fiber reinforcements to the plastic matrix to optimize properties such as mechanical performance. Lanxess expects AI to slash the development time for optimized formulations by more than half. Algorithms calculate forecast models for improved test configurations and parameters, enhance these models on the basis of the measurement results from each test, and propose an optimum formulation—a procedure for product development that outpaces traditional methods.

Polyolefins in the Lead

Sustainability efforts underway within the polyolefins arena include materials with recycle or biobased content and designing for recyclability.

One new milestone in sustainable PP is expected to result from the strategic cooperation between Austria’s Borealis and Finland’s Neste. Borealis, which last year made its U.S. manufacturing entry with a new PP compounding plant in Taylorsville, N.C, is aiming to produce renewable PP using Neste’s 100% renewable propane produced by proprietary technology, starting this year.

SABIC showcased its certified circular polymers produced using “pyrolysis oil” feedstock created from recycling of low-quality, mixed plastic waste otherwise destined for incineration or landfill. The resultant certified circular polymers boast quality equal to that of virgin polymers with outstanding mechanical and processing properties and purity. SABIC says these products are being used in development of consumer packaging for food, beverage, personal-care and home-care products by several brand owners.

SABIC also showcased its certified renewable polymers, which are virgin polymers based on second-generation, animal-free, biobased feedstocks such as waste from wood pulping. Both the circular and renewable polymers have been accredited through International Sustainability and Carbon Certification (ISCC Plus). SABIC’s internal cradle-to-gate life-cycle analysis of its renewable polyolefins found that from sourcing of raw feedstock to final production, each ton of renewable PE and PP can save up to two tons of carbon dioxide compared with fossil-based polyolefins, potentially reducing the use of hydrocarbon resources by up to 80%.

SABIC also discussed how its new enhanced mechanical recycling incorporates the maximum amount of recycle content without compromising the quality or performance needed for household, industrial and chemicals packaging. Incorporating up to 50% post-consumer resin (PCR), the company’s HDPE compounds deliver strong stress-crack resistance, even in thinwall packaging. SABIC is also offering a new HDPE “booster” grade to help incorporate PCR or increase the existing PCR content in bottles from 30% to 60%.

As part of its design-for-recyclability efforts, SABIC featured all-PE stretch-hood film to help replace EVA-based structures and PVC cling films.

SABIC showed examples of stand-up pouches made from its new biaxially oriented PE.

A major introduction along these lines was a new resin for biaxially oriented polyethylene films. The company showed examples of stand-up pouches made from BOPE, suitable for confectionary and snacks; frozen, fresh and dried fruit, vegetables and legumes; and packaging for personal-care products. BOPE boasts good printability, high mechanical properties and toughness, as well as very high seal integrity. SABIC’s new material also enables BOPE film to feature unique controlled, linear tear direction, thus making the package easy to open. This new product is also available as certified circular or renewable polymer.

SABIC’s new BOPE supports easy and full recyclability through enabling a mono-PE material structure in multilayer tenter-frame pouches.

ExxonMobil showcased new collatation shrink film made with its high-performance Exceed XP and Enable mLLDPEs, which allow for up to 40% recycle content with no compromise of performance.

Also from ExxonMobil were all-PE standup pouches made with recycled materials, thanks to the company’s collaboration with Hosokawa Alpine, Erema, and Henkel. The new packages combine 30% recycled standup pouch PE with 70% virgin ExxonMobil performance PEs such as Exceed XP and Enable mLLDPEs.

Dow showcased all-PE pouches that can be recycled for use in collation shrink film, along with its first recycle-grade LLDPE. Affinity CE contains up to 70% recycle content and is designed for multilayer shrink film used in applications like wrapping water bottles.

Borealis, Borouge and Henkel discussed industry collaborations on development of “highly-circular” flexible PE pouches. Two such standup pouches are a combination of virgin PE with high levels of PCR. Also underway are further developments in PE and PP monolayer pouches designed specifically for recyclability.

Braskem featured an expansion of its “I’m Green” portfolio to include a biobased EVA, as well as a PP homopolymer with up to 15% I’m Green PP that's being tested for food packaging.

Nova Chemicals launched VPs412 high-caulkability octene LLDPE sealant for all-PE high-speed food-packaging films. The company calls it a “game changer” as it is a single-solution resin vs. common use of LLDPE/plastomer blends.

Prisma 6910 is an in-situ produced clear impact PP copolymer for frozen-food packaging and clear refrigerator/freezer articles.

Braskem also launched new Prisma 6910, an in-situ produced clear PP impact copolymer targeted to clear frozen-food applications and clear refrigerator/freezer articles such as ice trays.

Borealis introduced BorPure RF770MO next-generation random PP copolymer for flip-top caps—a growing market segment. It reportedly offers proven cycle-time reductions of over 10% in some cap applications, thanks to its fast crystallization.

Borealis also launched next-generation Fibremod Carbon PP composites for automotive; these materials are made with second-use carbon fiber. Two low-density grades, CG210SY and CD211SY, boast better surface aesthetics and mechanical properties.

Sustainability, Higher Performance in Engineering Resins

As reported previously, chemical recycling of PS has been underway at Ineos Styrolution, which is also now collaborating in this undertaking with Trinseo. At the show, the company revealed that it has provided PS sheet containing 50% chemically recycled GPPS for production of yogurt cups by a leading European dairy manufacturer.

Trinseo, meanwhile featured PC/ABS blends with up to 70% recycle content. Trinseo also unveiled biobased and biodegradable TPUs for applications such as coffee pods.

Domo Engineering Plastics is now offering the Economy brand of 100% recycled nylon 6 compounds as well as Economy Air—recycled nylon 6 with recycled carbon fiber for automotive, aircraft and medical devices. When it’s acquisition of Solvay’s nylon 66 is completed this year, Domo will offer similar sustainable products. Domo also has collaborations on both mechanical and chemical recycling.

DSM announced that it is now offering both Stanyl and Arnite specialty nylons produced with 25-42% biomass and will aim for at least 25% on all its materials by 2030.

Ascend Performance Materials announced that it’s entering the nylon 66 film market with Vydyne PTR for food and industrial packaging. These resins boast excellent puncture resistance, high-temperature resistance, excellent aesthetics, and can be used 40% thinner than nylon 6 film resins.

Ascend Performance Materials announced that it’s entering the nylon 66 film market with Vydyne PTR for food and industrial packaging.

Ascend also launched new Vydyne ThermPlus, a heat-stabilized nylon 66 specially formulated for cable ties and fasteners used in automotive, construction and industrial applications.

Also new from Ascend are Vydyne XHT extreme high-temperature nylon 66 compounds for applications such as automotive charge-air ducts, where they can compete with PPA and reportedly offer better processability.

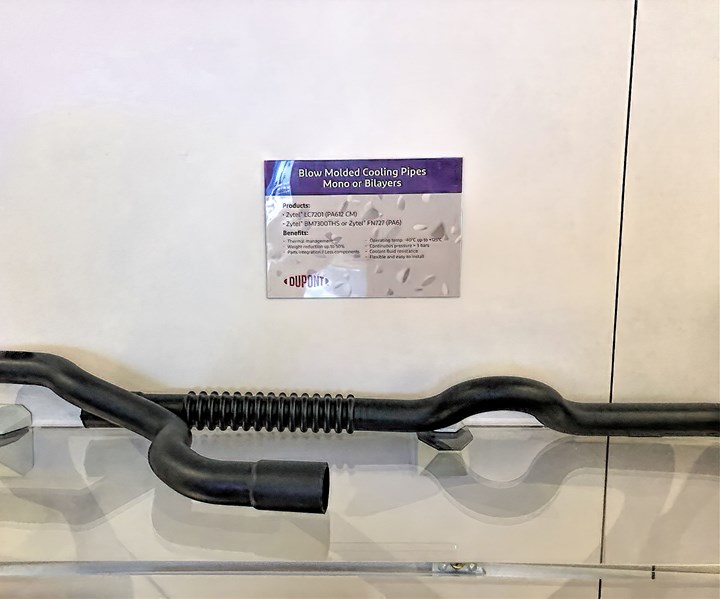

DuPont showcased a variety of new applications for its engineering resins, including its Zytel nylon 612, which is gaining attention in automotive applications such as blow molded cooling pipes—a technology that can be transferred to electric cars.

Zytel 612 nylon is getting increasing play in blow-molded automotive cooling pipes, a technology that can be transferred to electric vehicles.

Solvay Specialty Polymers launched what’s said to be the industry’s first “true” high-temperature PEEK. Because it boasts a true 2:1 ether-to-ketone ratio, unlike standard PEEK, Solvay says its KetaSpire PEEK XT is more aromatic and thus more rigid.

It also boasts exceptional chemical resistance, along with a 20º C/36º F higher glass-transition temperature plus a 45º C/81º F higher melting temperature. Applications include oil and gas connectors, automotive seals, E/E, and industrial components.

KetaSpire PEEK XT is said to be the first ‘true’ high-temperature PEEK.

Covestro showcased what’s said to be an industry-first compression molded, flame-retardant PC electric-vehicle battery housing that outdoes SMC housings in both performance and lighter weight.

Covestro also showcased an impressive array of prototypes of PC-based 5G antennas ranging from larger, lighted units to small compact units.

SABIC showcased a 3D-printed prototype of a structural body-in-white honeycomb component made of its Xenoy XTC— a new high-heat PC/PBT. It is designed for structural support of battery packs in electric vehicles.

New LSR Elastomers

Wacker showcased its portfolio of self-adhesive LSRs with low coefficients of friction. It comprises two new product lines: Elastosil LR 3671 for applications in food technology; and LR 3675 for automotive applications. Wacker also showcased its Silpuran 6760/50 LSR for medical applications, with comparable surface properties. All three products are self-adhesive to metals and selected thermoplastics. When cured they form elastomers with dry, low-friction surfaces, enabling cost-effective large-scale production of injection-molded hard/soft composites.

What was newly unveiled is the combination of both technologies in one single product, achieved by means of a special formulation concept. The LSR grades can be customized for different fields of application by selecting appropriate formulation ingredients.

Silicone elastomers made from Elastosil LR 3671, LR 3675 and Silpuran 6760/50 have coefficients of friction that are 50-70% lower than those of comparable standard LSRs. The friction-lowering effect is achieved without exuding oil as happens in oil-bleeding silicone elastomers. That suits the products for use in the manufacture of components with low-friction surfaces that must be kept oil-free.

Like other Wacker self-adhesive LSRs, the new compounds adhere to thermoplastics such as nylons and PBT. Strong chemical bonding takes place on application, eliminating the need to pretreat the plastics. The same is true for metal surfaces, with the new products said to exhibit excellent adhesion without any pretreatment in many cases. With appropriate machinery and mold technology, the LSRs can be molded directly onto the substrates.

As reported in our September K preview, Wacker also featured its non-post-cure Elastosil LR 5040 liquid LSR for sensitive applications and reduced volatiles. LR 5040 cures to translucent elastomers whose volatiles content – without thermal post-treatment – usually ranges from 0.2% to 0.3% by weight. So, even in the non-post-cured state, they are already far below the limit value of 0.5% that applies to the volatiles content of silicone articles intended for food contact and baby-care applications.

Elastosil LR 5040 is a non-post-cure LSR with low volatiles.

Dow, which showcased numerous fast-growing applications for LSRs, unveiled an oil-bleed LSR that contains another silicone that rises to the surface for lubrication of automotive connector seals—a market sector with over 10% annual growth.

Other Materials News

Milacron’s DME Components division launched FreshStart, a patented, “revolutionary,” all-purpose mechanical purging compound. The MC-2 and GP grades are two in a series of purging compounds designed for the removal of unwanted pigments, polymers and contaminants without leaving residue. Suited to quick color changeovers—particularly liquid-pigment dispersions, dyes and engineered resins, FreshStart is said to be a safe, non-abrasive, non-hazardous purging agent developed around Generally Recognized as Safe (GRAS) ingredients under FDA 21 CFR.

Vestamid e²X from Evonik is said to set new standards in TPEs. With its reportedly excellent transparency, color stability and glossiness, the recently developed PEBA reportedly outperforms typical resins in this class. Its properties, such as excellent low-temperature impact strength, high elasticity, good resilience, and low density are said to suit Vestamid e²X to high-end applications in sports and consumer goods as well as automotive.

Kaneka unveiled the Kaneka Biodegradable Polymer PHBH, produced by a microorganism fermentation process, in which plant oils and fatty acids are used as a primary raw material. This biobased and biodegradable polymer is suitable for food utensils, containers and packaging materials. It is said to be strongly resistant to heat and hydrolysis and can act as a water-vapor barrier.

Kaneka PHBH is said to be the first 100% plant-based biopolymer to offer both flexibility and heat resistance.

Kaneka PHBH is said to be first 100% plant-based biopolymer to offer both flexibility and heat resistance. It exhibits properties ranging from hard to soft, as well as a number of key characteristics of PE and PP. It also boasts very good printability and dyeability. The company is refining the composition and processing to further improve the strength and tear resistance of packaging films, agricultural mulch films and composting bags. Kaneka is also pursuing opportunities in high-durability molded products such as bottles and containers, automotive interiors and electrical equipment.

Additives News

Wacker introduced Genioplast Pellet 345, a silicone-based additive that compounders can use to reduce the hardness of TPEs—particularly TPUs—used in sports and leisure, microelectronics, automotive, and medical devices. Wacker enhanced the compatibility of silicone with polyurethane by incorporating polar groups, which produce better dispersion in the polyurethane matrix and stabilize the bond between the silicone and polyurethane.

Wacker enhanced the compatibility of silicone with polyurethane by incorporating polar groups.

The result is a polar-modified silicone copolymer made up of elastic, soft silicone segments and functional, polar organic polymer segments. The new additive helps TPUs meet the silky and soft feel increasingly sought by consumers.

Genioplast Pellet 345 is a silicone-based additive that can reduce hardness of TPUs to meet the silky and soft feel sought by consumers.

Brüggemann unveiled reactive chain modifiers for nylon recycling. The Bruggolen M series reportedly allows for precise and reproducible adjustment of relative viscosities, by either lengthening excessively short chains or shortening those that are too long. Producers can use small amounts of these modifiers to tailor relative viscosities to their needs in a single compounding step. The resultant upcycled materials reportedly are suitable for the same applications as prime materials of similar viscosities. This removes the need to blend the recyclate with prime polymers and opens up a wide range of possibilities for secondary nylon materials that meet the quality requirements of the molding industry.

Bruggolen TP-M1417 is said to provide a precise and robust way of shortening the excessively long molecular chains of high-viscosity nylon waste from materials such as films or cast nylon. Addition of just a small quantity of the additive during a single extrusion step can decrease the viscosity so that the polymer can be injection molded. The final viscosity can be very accurately controlled by adjusting the quantity added.

Bruggolen M1251 reportedly makes it possible to compensate, by linear chain extension, for the reduction in molecular weight arising from the degradation caused by processing and previous use. As a result, the mechanical properties of the recyclate can be improved to match those of prime material. M1253, available as a smaller pellet size of the same additive, makes for easier dosing during compounding. Both modifiers are supplied as dust-free granules suitable for accurate metering.

SI Group launched Ultranox LC (low color) PP additive one-packs that include an undisclosed mineral that boosts color stability. This new series for color control of polyolefins was developed to address trends in PP markets, such as to bigger and faster extrusion lines. The portfolio consists of LC PP701, a color protector for BOPP; LC PP301, for cost-effective color protection in general-purpose applications; and LC PP501 for fibers.

FRX Polymers showcased expanded applications for its Novia non-halogen polyphosphonate-based flame retardants, which are now being used in PC/PBT for medical and E/E housings, where they boast excellent flame-retardance as well as chemical resistance and heat aging.

Wacker’s Vinnex additive for creating new biopolymer blends is based on PVA.

Wacker launched a new line of additives designed to improve the properties of bioplastics. The Vinnex line includes versatile additives for biopolyester or blends of biopolyesters—such as PLA (polylactic acid) and PBS ( polybutylene succinate), organic and inorganic fillers, and starch. Key applications for Wacker’s additives include plastic packaging or combinations of plastics and paper such as cardboard box coatings or the moisture-barrier lining in paper cups.

The Vinnex additive system is based on polyvinyl acetate (PVA) which makes it possible to combine various biopolyesters, thus selectively influencing the properties of the polymer blend. This reportedly opens up a broad, customizable product range for biobased plastic blends.

Related Content

Polymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.

Read MorePrices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreRead Next

K 2019 Preview: Resins & Additives for Sustainability in Cars, Electronics & Packaging

Material suppliers are committed to the ‘Circular Economy,’ as evidenced by their adoption of new technologies, product introductions and collaborations.

Read MoreIneos Styrolution and Agilyx to Build New Polystyrene Chemical Recycling Plant in Illinois

The facility will be capable of processing up to 100 tons per day of post-consumer polystyrene and converting it into a styrene product that will go into the manufacturing of new polystyrene products.

Read MoreRecyclable All-PE Pouches: Sustainable Opportunity for Film Extruders

Sustainability and the Circular Economy are both a challenge and an opportunity to flexible packaging producers. Recyclable pouches based on all-PE multilayer structures, utilizing new resins and perhaps techniques like MDO or biaxial orientation, appear to be major contenders against glass, metal, and multi-material film structures.

Read More