High-Tech Molder Goes Digital for QC

Allegheny Performance Plastics turned to 1factory's cloud-based manufacturing quality control software for streamlined, paperless quality systems.

Allegheny Performance Plastics is a high-tech molder creating high-tech parts for some very high-tech customers in markets such as automotive, aerospace, defense and medical. Need proof? Look no further than its IATF 16949, AS9100, ISO 9001 and ITAR certifications. When it came to some aspects of its quality control, however, like many manufacturers, it relied on some very low-tech solutions: pencils, binders, disparate spreadsheets, manually entered data and screenshots turned into PDFs sent to customers.

“It’s kind of crazy that we have this digital information available on these inspections but then we’re taking that, creating a hard copy from it and then storing it in a banker’s box,” says Greg Shoup, Allegheny CTO.

In the past, Allegheny used multiple systems for CAPA, supplier quality, PPAP, FAI and SPC, with paper-based record retention. SPC data was batch loaded into SPC software offline, with data from digital CMM reports transposed to handwritten retention records. Ultimately, this meant operators and technicians had minimal visibility to run chart data, while the manual process exposed the company to the potential for human error.

Screenshot of the drawing ballooning function in 1factory’s software. Source: 1factory

The 1factory was created with companies like Allegheny in mind, providing cloud-based manufacturing quality control software that makes it easier to collect, manage, analyze and report inspection and testing data.

“Companies that come to us say, ‘We have several robust systems in pace, but we’re still doing all of our quality control on paper, and it’s really becoming a bottleneck,’” explains Jon Facer, director of customer success at 1factory. “You don’t want to have to spend production time just checking parts.”

The demanding jobs that Allegheny takes on require precision and documentation of that precision. “Our customers usually aren’t in clothes hangers or furniture,” Facer says. “It’s jobs where it’s going to be aerospace or medical device or something going in space — mission-critical components — where if one of these diameters is off or the weight is wrong it will cause major issues.”

Under the former quality regime, Shoup says Allegheny had to create a new PPAP specific to each customer, eliminating the possibility of efficiency of commonality. For SPC, the records for in-process inspections were all handwritten on paper before being batch uploaded, creating “obvious transposing issues,” Shoup says, which was also an issue with CMM reports, which were transposed to handwritten retention records.

Beyond the inefficiency and potential introduction of human error, Shoup says the former process also didn’t provide any real-time transparency to a production run’s quality. “The biggest issue was operators and technicians that are working with these parts have minimal visibility to just a simple run chart to see where the data was trending,” Shoup says. “How it was behaving within its control limits? They couldn’t see any data beyond the part they were measuring right in front of them.”

Allegheny made the switch to 1factory and saw immediate benefits, including the ability to see SPC data in real time versus days later after bulk uploading in the old systems. Since adopting the software, the company says the biggest savings in time and resources have come from ending manual transposing and navigating multiple systems to retrieve quality information.

“Without a system like 1factory, manufacturers go through an agonizing quality planning process,” Facer explains. “When a drawing is received from a customer, someone uses a PDF editor or even a pen to mark each dimension that needs to be inspected. These dimensions and tolerances are then manually copied into a static inspection sheet. For parts with hundreds of dimensions, this process generally takes several hours.”

The 1factory software cuts this down to a couple minutes. The software automatically reads all dimensions on the print and copies them into the inspection plan. The quality engineer can then define sampling rules, inspection methods and other QC instructions. When it’s time to inspect the part, the operators log into 1factory, input the part number and job number, and an inspection sheet is created, showing all instructions and requirements.

The 1factory’s platform supports SPC and real-time data analytics. Source: 1factory

Not only does 1factory save several hours per week internally but Allegheny’s customers are able to view a live feed of their jobs, including all SPC and process capability calculations.

“Customer access has saved us a lot of time, because we were screenshotting run charts, creating PDFs and sending them data,” Shoup says. “Then we found out we can just say, ‘Hey, customer X can see these plans or part numbers. When they’re curious or they want to know something, they can go look at it.’”

That openness conveys a confidence in its production capabilities which is also beneficial to the relationship. “It really opens their eyes to how transparent we really are,” Shoup says. “Until you get to a point where you are sharing on that level, everyone always thinks you’re hiding something. This was a way to get them to see, ‘They’re showing us everything as it’s literally going into the system.’ We’re not hiding anything.”

Nika Martin, CMM operator at Allegheny Performance Plastics, completes a quality check. Source: Allegheny Performance Plastics

Related Content

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Five Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

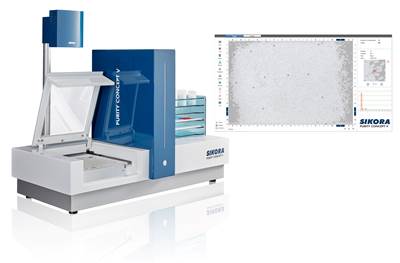

Read MoreOffline, Automated Inspection and Analysis Tool for Plastics

Sikora’s Purity Concept V reportedly combines the functionality of an optical light table with an automatic evaluation, said to be unique to the market.

Read MoreAtop the Plastics Pyramid

Allegheny Performance Plastics specializes in molding parts from high-temperature resins for demanding applications as part of its mission to take on jobs ‘no one else does.’

Read More