The process technician walked into my office with a perplexed look on his face and proclaimed that he had just shot a 16-cavity mold at least 20 times and noticed that no parts were being made. Upon hearing this news, I asked—as politely as I could—where he thought that plastic might be going? “Not sure,” was all he could muster.

Upon arriving at the press, it was obvious where the plastic had gone as the top of the now smoking control box had been blown open and hot resin was still oozing from around the electrical connections. “It’s going to be a long day,” I thought to myself.

Having more than 30 years of bench time repairing and maintaining molds, along with another 15 years instructing hot-runner courses here at MoldTrax’s maintenance training center in Ohio, I am still surprised at the number of hot-runner leakage stories that our attendees share. Even though hot-runner technology has greatly improved over the years since it was first introduced to the industry some 60 years ago, we still struggle with this issue. Why?

It is All (Mostly) About the Startup

When I posed this question to Bob Duffy of Polymer Cleaning Technology, he stated that most manifold leaks that his company sees are due to improper startups, or what is referred to as “cold starts.” Many manifolds are designed with “cold clearance” between the nozzle component stack and the retainer plate to allow room to grow, which prevents damage to these components from thermal expansion at operating temperatures.

Just because the manifold and nozzles have reached operating temperatures does not mean that they have fully expanded to reach proper sealing pressures.

The confusion lies in the fact that just because the manifold and nozzles have reached operating temperatures does not mean that they have fully expanded to reach proper sealing pressures. So, when processors see that a set temperature has been reached, they assume that it is OK to shoot the mold. What needs to be understood is that all systems need a certain amount of “soak time” to reach maximum expansion, thus creating the required sealing pressure between the manifold and the back of the nozzle, which is where most leaks occur. If full expansion is not reached, it will leak at this critical seal point every time.

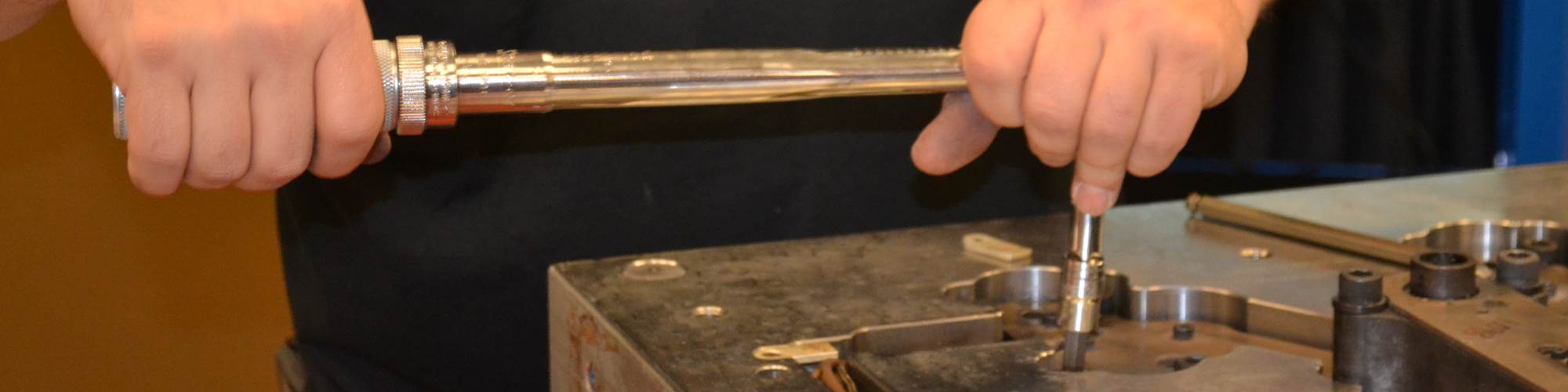

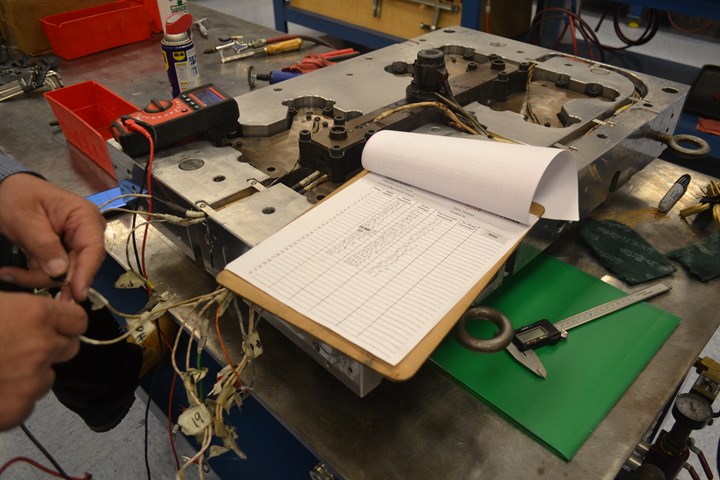

It is important to take reference measurements to insure all components go back together correctly. (Photos: MoldTrax)

In MoldTrax’s hot-runner course, we drive this point home by measuring components first in a cold state, or room temperature, and then after heating. This exercise shows that a standard nozzle can reach typical operating temperature—like 450°F—within as little as 3 min but requires an additional 15 min to expand fully. Due to the mass involved with manifolds, operating temperatures are achieved more slowly—like 30 min—but still need additional time to fully expand. Proper soak times should be confirmed with the manifold supplier; or, if possible, take your own measurements. The larger the manifold, the longer it needs to soak.

This thermal expansion is also why it is important to follow the proper sequence when starting a hot runner. The manifold should always be heated first as it will expand more slowly than the nozzles since it has more mass. Manifolds are also isotropic, meaning they expand and contract equally in all directions. If the nozzles are heated first, they can expand and exert enough pressure against the manifold seal area to create drag marks as the manifold expands in a linear direction, degrading the integrity of the shutoff.

It is also important to maintain the area where the press nozzle seals against the mold sprue bushing. Make sure the nozzle radius and the mating radius of the sprue are the same. Also, if the nozzle isn’t lined up correctly with the sprue, or if it is hobbed or worn, plastic will leak past the sprue and travel to internal parts of the manifold system.

Detecting Leaks Electronically and Visually

Many smart controllers can help detect leaks before the entire manifold is completely encapsulated by installing thermocouples at various locations around the manifold that are designed specifically to detect leaking plastic. Another method relies on the fact that excess plastic surrounding manifold components acts like a heat sink, requiring more power to the encapsulated heater to sustain a set temperature. This rise in power is identified by the controller, which can set off an alarm or simply shut down the press. Yet another method tracks the broken thermocouple and heater connections as the leaking plastic makes its way through various wiring channels. Sensors can detect if the broken connections are in a straight line, as you would see in a leak, setting off an alarm, vs. normal random issues.

Excess plastic surrounding manifold components acts like a heat sink, requiring more power to the encapsulated heater to sustain a set temperature.

Unfortunately, small leaks that eventually fill wire channels over a longer time can be difficult to detect, as they will not cause abrupt variations in temperatures that many controllers rely on to detect a leak. With some of these molds, I have milled the wiring channels in the manifold plate that extend through the plate, creating a sight line through which to inspect for leaks. I can then simply shine a light through the channel; if there is a leak, no light will shine through and be seen by a helper on the other side of the mold. Larger leaks cause issues more easily recognizable, such as shooting a mold 20 times and seeing no parts, or random non-filling or incomplete filling of parts.

Measurements when key components are cool and fully heated give a baseline understanding of how much expansion takes place and when a hot runner is fully “soaked.”

That is why it is important to periodically, based on a cycle count, disassemble a manifold and components to look for signs of leakage, excess residue or off-gassing. With valve-pin systems, wear between the valve pin and the valve-pin bushing will result in a build up of off-gas or resin that will be apparent in the clearance hole through the manifold in which the valve pin travels. As the pin and bushing wear, resin will load up here first and then migrate up into the piston cup assembly, which will impede forward travel of the pin, resulting in an improper shutoff at the gate and a bad part.

Fixed gates are less problematic since they do not have to maintain a fit between valve pin and bushing, but even these need to be disassembled occasionally to check for wear between the manifold and nozzle, and any signs of leakage.

Preventing Leaks

Advances in hot-runner technology have improved greatly over the years, with some manufacturers even offering guarantees against leakage for millions of cycles and multiple years. But the fact is there are thousands of older manifolds still producing today and some are just difficult to start and run without experiencing leakage between the nozzle and manifold or the radial shutoff between the nozzle tip and the cavity gate insert.

Working in the press can save time but can also cause issues if the technician reassembles the plates while there is a large temperature variance; try to keep plates within 10°F of each other.

Preventing leaks starts with ensuring that the manifold and components are clean and assembled correctly with no loose or missing bolts, pinched wires, misaligned dowels, brass shavings from tools, or incorrect components. Once this is accomplished, obviously a proper startup is required to ensure adequate expansion of the components to seal.

In-Press Servicing of Hot-Runner Tools

To prevent leaks between the nozzle-tip seal diameter and the gate insert, we must keep in mind that since manifolds are isotropic, the expansion variance between plates comes into play with molds that are serviceable in the press. When the cavity plate is moved over to expose the nozzle tips for cleaning or replacement, the cavity plate will cool off quickly, especially if the water is left on, while the nozzle/manifold side will retain heat much longer. This causes a misalignment between the warm nozzles and colder cavity-insert centerlines as the plates are now at two different temperatures.

Working in the press can save time but can also cause issues if the technician reassembles the plates while there is a large temperature variance. It takes very little pressure to damage the nozzle seals during a clamp-up in the press, especially if low-pressure mold protection is not being used. Just bumping the two plates together is enough to cause a ding or flat spot in the seal that will leak under processing conditions. Try to keep plates within 10°F of each other to reduce this misalignment.

So, the bottom line in reducing hot-manifold leakage is to first understand how expansion works for you and against you in any system. Create startup and shutdown procedures and follow them. Maintain manifolds by documenting and following maintenance procedures during cleaning and inspection. Hot-runner systems can save companies money through more efficient molding of parts, but they also come with specific requirements that call for shops to get “skilled up” to take advantage of that opportunity.

ABOUT THE AUTHOR: Steve Johnson is the President of MoldTrax Maintenance Solutions in Ashland, Ohio, a provider of maintenance training products and services. His 40 years of experience in the tooling industry includes eight years as senior tooling engineer for Abbott Laboratories and 24 years as a toolmaker at Calmar Inc. Prior to Calmar, he served six years in the U.S. Navy working as a jet mechanic on the A4L Sky-hawk, and majored in mechanical engineering at Southern State University. He designed and developed the MoldTrax documentation software system for tracking mold performance and maintenance. Contact 419-281-0790; steve@moldtrax.com; moldtrax.com

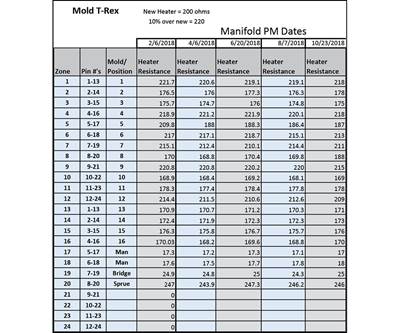

Documenting ohms during preventive maintenance is an important part of working proactively to determine the condition of heaters and thermocouples.

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreRead Next

Mold Performance: Tap Into the Power of Data Collection

Collecting core data in a transparent way allows molders to drill into the true cost of tooling issues and develop real goals to keep production flowing.

Read MoreTime to Turn Up the Heat on Your Hot-Runner Maintenance Program

Molders are running more hot-runner manifolds than ever, a trend that’s expected to continue. But once you have them, you need to keep them in shape. Follow these tips to get going.

Read MoreBreaking Down Hot Runner Maintenance

Improving a manifold’s maintenance plan requires specific skills and knowledge of its functioning areas.

Read More