It's Time to Get to Know Your Way Around Bioplastics

If you’re thinking about adding bioplastics to your portfolio of processing capabilities, it’s best to first find out what separates them from traditional synthetic polymers and how their differences will affect you.

If you’re thinking about adding bioplastics to your portfolio of processing capabilities, it’s best to first find out what separates them from traditional synthetic polymers and how their differences will affect you. Until recently, the typical perception of biopolymers has been dominated by biodegradable resins such as PLA (polylactic acid), PHA (polyhydroxyalkanoate), and starch-based compounds. Today, partially bio-derived compounds have emerged as an addition to the biopolymer spectrum. These truly engineered materials are not biodegradable, but offer increased bio-content relative to conventional resins and performance capable of serving durable applications.

This broadening of the bioplastics spectrum gives both processors and designers greater options. It also means that developing an expertise in processing these materials now takes on an added dimension.

BioPOLYMER types & characteristics

Biopolymers known for biodegradability include starch-based polymers. Injection molding and film grades of starch-based materials are currently available, while extrusion blow molding grades are under development and expected to come online soon. Shopping bags and agricultural mulch films are two of the success stories in this category. Here the unique attribute of compostability is valued, and the price premium that biomaterials command over traditional polymers is acceptable to the market, based on the value it brings throughout the supply chain.

Bio-derived polyesters also known for their biodegradability, such as PLA and PHB, appear in applications ranging from packaging to durable goods. PLA, produced by NatureWorks LLC (natureworksllc.com) has found a niche in thin-walled rigid packaging and thin, biaxially oriented films. On the other hand, PLA suffers from several performance limitations, including an inability to withstand continuous use temperatures above 130 F, lower barrier properties than traditional film products, and lower impact resistance. Many efforts are under way to overcome these limitations in certain application areas, through such means as use of additives and other compounding ingredients.

PHB and its copolymer PHBV, produced by Tianan (tianan-enmat.com), have been used in many film and semi-durable applications. They and are also suited for applications such as sutures, mulch films, shopping bags, tableware, and packaging. These polymers degrade in various environments, including marine, soil, and compost facilities.

PHA, trademarked Mirel, is just being commercialized by Telles (mirelplastics.com), a joint venture of Metabolix and Archer Daniels Midland. It has a performance and application profile generally similar to PHB and PHBV.

Materials known for their bio-based content include polyamides, or nylons, that are wholly or partly bio-derived, such as nylon 11 and nylon 610, both available from multiple sources. There are also renewably sourced TPEs such as Pearlthane Eco TPUs from Merquinsa (merquinsa.com), Versaflex BIO and OnFlex BIO from PolyOne (polyone.com), Hytrel RS copolyesters from DuPont (plastics.dupont.com), and Pebax Rnew polyether block amides from Arkema (arkema.com). There are also some brand-new engineering thermoplastics with bio-based content, such as DuPont’s Sorona EP PTT polyester and a growing field of bio-based alloys with conventional polyolefins, styrenics, or engineering thermoplastics. Performance of these materials is much closer to that of conventional engineering thermoplastics, TPEs, or other conventional polymers in the blends.

Processing specifics

While each biopolymer has its own processing profile, there are a few overall caveats. Most biodegradable polymers need to be processed at much lower temperatures than resins such as PS or PET because they have lower melting points and are temperature sensitive as well. Some biomaterials must be dried in advance, much like PET. Also, molders should be aware that PLA and PHA have a relatively slow rate of crystallization, which prolongs cooling times and affects heat resistance of the final application.

Bio-based and partially bio-based polymers, on the other hand, behave more like engineering thermoplastics when molded or extruded. Melting points are consistent with the non-bio versions of these materials. They may still require drying, however, for optimal processing.

The biggest issue surrounding many unmodified biodegradable plastics is their lack of heat resistance. This requires processing at a much lower temperature than most processors typically use. A secondary issue concerns moisture sensitivity. Moisture levels need to be controlled and drying is recommended. For instance, PLA materials are moisture sensitive during processing, but starch blends are moisture sensitive only in end-use applications. On the other hand, PLA is not moisture sensitive at all in end-use applications.

Bio-derived polyamides and TPEs have processing characteristics similar to their non-bio counterparts. PolyOne’s Versaflex BIO TPEs, in particular, have a robust processing window and excellent processability with multiple fabrication options, including blow molding, extrusion, and injection.

Performance considerations

Current applications for biomaterials illustrate the performance space they occupy, normally one of the following:

•Disposable goods: Short product life, lower performance required;

•Durable goods: Long product life, higher performance required.

Disposable goods can be found in applications such as packaging and consumer goods, and here processes generally range from film and foam to blow molding and thermoforming. Durable goods made from bio-based polymers can include housings for mobile phones, PDAs, laptops, automotive interior components, building materials, and appliances. Typical processes in this category are injection molding and extrusion.

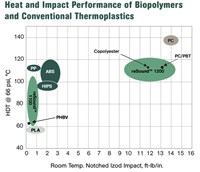

While most biodegradable materials are limited in resisting heat and impact, bio-based compounds offer a unique balance of temperature, impact, and cost performance, making them good candidates in durable applications across a variety of markets.

Both bio-based and biodegradable polymers represent an exciting dynamic in the polymer industry, but there are many considerations in selecting these materials. Chief among them are cost, availability, and performance requirements. Additionally, it is important to define objectives such as biodegradability and/or bio-content.

Most biomaterials are currently found in niche applications; however, it is clear that future technology advancements will broaden the capabilities and reduce the cost of producing them, opening more market and growth opportunities in the years ahead.

Another marker for the continued growth of these materials involves the drive to make products more sustainable. While this term is not well defined, most manufacturers have some type of sustainability initiatives in place, and are investigating the addition of either biodegradable or bio-based materials that can help to address the carbon footprint of their products. Processors who are able to meet this growing demand stand to gain a competitive advantage.

About the Author

Marcel Dartée, global marketing director for biomaterials at PolyOne Corp. in Assesse, Belgium, is a recognized leader in the emerging field of bioplastics. He currently serves as a board member on the SPI Bioplastics Council, the European Bioplastics Organization, and the Dutch Bioplastics Association.

Related Content

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MorePrices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Read MoreTracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More