Medical Tubing: Tinier Than Ever And Much More Complex

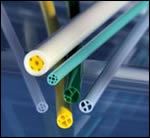

Medical tubes are becoming ever smaller and thinner while adding new features like high-tech material combinations, more wire braiding/wrapping, and heat-shrink sheathing for strength and kink resistance.

Smaller diameters, thinner walls, and more complex structures—that’s a short description of the latest in medical tubing, which was exhibited at February’s MD&M West show in Anaheim, Calif. These micro-fine products nowadays are more apt to incorporate high-performance engineering resins, wire braiding or wrapping, and shrink tubes to hold increasingly complex structures together.

“The market is going toward more complex composite tubes, starting to use more and more materials in a given tube, and more wire wrapping and braiding,” states Tim Lynch, v.p. of operations for tubing maker MicroLumen Inc., Tampa, Fla. “We’ll take a pure PTFE tube ID, then braid stainless-steel wire over it. Then we might add four different materials on the OD to change stiffness along the length—nylon at one end, changing to Pebax (polyether-amide TPE from Arkema), in a sequence of softer and softer durometers, then a shrink tube of FEP over the top to solidify it all.”

Sometimes the composite is produced by one processor in-house. Sometimes different companies supply different layers. MicroLumen, for example, makes the PTFE tubes and over-braids them in-house, buys the Pebax and shrink tubing, and then assembles the composite.

New composites like these are driven by growing demand for minimally invasive surgery, tubing for wires to stimulate nerves and regulate heartbeats, tubes for vascular access and urology, and ever-smaller catheters including those for surgery on infants.

Multiple-durometer sections on PTFE-lined shafts makes steerable composite tubes that can be moved into position within the vascular system, says Sean Lynn, associate director of extrusion development at Teleflex Medical, headquartered in Kenosha, Wis.

With smaller micro tubing comes demand for new or improved characteristics inside and out. Tubes have to thread more easily into the body, requiring more lubricated outer surfaces; and wires have to thread more easily through tubes with smaller clearances inside, requiring lower coefficients of friction on interior surfaces. These requirements often dictate using a composite of PTFE inside and a more conventional thermoplastic outside.

More wire braiding

“Braiding and coiling are getting more refined,” says Duane Dunn, president of Dunn Industries Inc., Manchester, N.H., which has done over-braiding in-house for five years. In-house braiding with stainless-steel micro wire is growing rapidly, as finer tubing requires braiding to add burst strength or prevent kinking. Some firms like Precision Extrusion Inc., Glens Falls, N.Y.; Putnam Plastics Co. LLC, Dayville, Conn.; and Teleflex Medical have done wire braiding in-house for years.

Other companies are now jumping into braiding and expanding rapidly. One micro-tube maker (which doesn’t want to be identified) invested in 15 braiders in the past two years and has just ordered two more. Braiders work around the clock and don’t need operator supervision. If a wire breaks, they just shut down.

Steeger USA Inc. in Inman, S.C., is a major supplier of customized micro-tube braiding machinery. It uses components from Steeger in Germany, but is an independent company. Steeger USA claims to make braiders for smaller tubes than other equipment can handle—as small as 0.005 in. OD currently, and it is working on even smaller sizes. Steeger braids round wire down to 0.0005 in. and flat wire down to 0.003 x 0.0035 in.

At MD&M, International Polymer Engineering Inc. in Tempe, Ariz., unveiled a new line of flexible endoscopic micro tubes consisting of solid PTFE spiral wound with stainless-steel micro-wire and then coated on top with an extruded layer of porous PTFE. “It’s unusual to bond solid PTFE to porous PTFE,” says International Polymer president Anthony Green. “Solid PTFE gives lubricity on the inside. Porous PTFE allows embedding of wire and bonding.” Two years ago, International Polymer introduced an earlier generation of the tube, called FluoroFlex, in which porous PTFE was extruded over solid PTFE with no wire in between.

Two firms introduced the first wire-braided FEP tubes at MD&M. Teleflex showed tubing with 0.004-in. wall thickness and IDs down to 0.009 in. Medical Profiles & Engineering (MP&E), Minnetonka, Minn., displayed tubing with a 0.005-in. wall. MP&E has braided in-house for about five years.

Raumedic in Leesburg, Va., launched a new micro tube capable of 1200-psi pressure. It has a TPU inner tube 0.035 in. thick that is over-braided with polyester yarn and then coated with more TPU on top. Raumedic does some of its own over-braiding now but plans to braid 100% in-house within six months.

MP&E also braids onto a TPU sheath with 0.005 in. OD and onto a coextruded tube with a TPU inner layer and either Pebax or HDPE outer layer. The latter has 0.005-in. ID and 0.008-in. OD.

Precision Extrusion and Putnam both braid over multi-lumen tubes. “The challenge is not to collapse the lumens,” says Putnam president James Dandeneau. Putnam recently began to vary the pitch in spiral winding to control product flexibility or reduce the amount of metal in areas where less kink resistance is needed or where side ports need to be cut.

Teleflex Medical produces multi-lumen tubing as well, with FEP-lined lumens to improve electrical isolation from the metal braiding and to make it easier to pass wires through.

New use of PEEK

High-heat, high-priced PEEK resin from Victrex has been used in small pharmaceutical tubes for years because of its chemical resistance. A medically implantable grade has been available since 2001 from Invibio, a unit of Victrex. A handful of companies use PEEK for medical micro tubes.

Zeus Inc., Orangeburg, S.C., is the world’s only maker of heat-shrinkable PEEK tubing, which it launched in 2005. Wall thickness is as small as 0.002 in. before shrinking and 0.004 to 0.010 in. afterward. Expanded ID ranges from 0.057 to 1.250 in. The ratio of shrunk to preshrunk wall length (circumferential) is 1.3:1.

Putnam made its first PEEK micro tubes in 1996, Precision Extrusion did so in 2003. Both developed customized equipment to handle the high processing temperatures of up to 700 F. Precision Extrusion makes PEEK tubing with up to four lumens, walls as thin as 0.006 in., and ID of 0.011 in.

PEEK tubes insulate wires to protect medical devices like pacemakers against short circuits. Besides high dielectric strength (>500 v/mil), it boasts chemical inertness, kink resistance, and low coefficient of friction (0.35 to 0.5). But PEEK is corrosive to extruders, so the barrel and screw require special metallurgy. “Everything about the machine has to be able to withstand 1200-1500 F temperatures, or it just won’t last,” says one engineer familiar with PEEK extrusion.

But the big difficulty is controlling micro-tube dimensions while the PEEK cools. The resin needs to achieve maximum crystallinity in order to achieve top physical properties, so cooling has to be slow and controlled.

Thinner and thinner

Both thermoplastic and silicone rubber tubes are achieving new thinness records, especially the latest heat-shrink tubes. Heat-shrink polyester (usually PET) and PE tubes replace spiral wrapping with thin film and adhesive to cover tiny high-pressure catheters, micro-wire devices, and joints between tubes. Shrink tubes can also insulate electrically and compress the OD of a micro wire bundle.

Advanced Polymers has made polyester shrink tube for 18 years, but five years ago began making it with 0.0001-in.-thick walls—“significantly thinner than anyone else can produce,” according to Robert Bley at manufacturers’ rep. David Schnur Assoc., Menlo Park, Calif. In 2006 Advanced Polymers also produced polyester heat-shrink tube with the smallest ID on the market—0.006 in.

PE shrink tube typically shrinks much more than PET. Extrumed LLC in Placentia, Calif. (which merged last year with Extrusioneering in Temecula, Calif.), introduced PE shrink tubing two years ago with walls as thin as 0.00025 in., expanded ID from 0.010 to 0.30 in., and shrink ratio of 10:1. Extrumed makes the initial tubing, sends it out for radiation crosslinking, and then reheats, inflates, and stretches it.

Cobalt Polymers in Cloverdale, Calif., claims to make the world’s only Pebax shrink tubes. It makes one with walls as thin as 0.001 in. and 0.010-in. OD, and another with 0.002-in. walls and 0.012-in. OD. Both have shrink ratios of 2:1 or 4:1. Cobalt also introduced ultra-thin polyolefin shrink tube at MD&M with walls as thin as 0.002 in.

Holes are getting so tiny they’re literally invisible. Precision Extrusion last year developed a thick-walled PVC micro tube with 0.26-in. OD and ID of only 0.0018 in., which can be seen only under a microscope. The tube is for highly controlled fluid transfer, such as for chemotherapy. Previously, Precision Extrusion’s smallest PVC tubing ID was a barely visible 0.003 in.

MicroLumen recently introduced a thermoset polyimide lead tube (produced by casting over a mandrel) for nerve stimulation with 0.0005-in. wall thickness (0.003 in. ID x 0.004 in. OD) and tolerance of ±0.0002 in. on ID and 0.00025 in. on wall thickness.

Specialty Silicone Fabricators, Paso Robles, Calif., has made silicone micro tubes with walls as thin as 0.003 in. The company, which builds its own dies, says this product uses its thinnest die clearance yet.

Medical tubes also are finding ways to cram in more and more lumens. In early March, Putnam produced a tube of soft Pebax with 0.3-in. ID, 0.4-in. OD, and 25 lumens, believed to set a new record. Specialized Engineering in Stockton, Calif., introduced a 22-lumen nylon micro-tube two years ago with 21 small lumens around a bigger central lumen with 0.100-in. ID.

Putnam and MicroLumen have produced tubing with one or two lumens that have inner linings of a different material. For about 10 years, Putnam has offered lumens lined with extruded TP polyimide or PE. For about five years, MicroLumen has produced lumens with an inner lining of cast polyimide that is over-wrapped with PE shrink tubing.

More slip inside & out

Coextrusion is growing in popularity as a way to make micro tubes more slippery inside and more lubricated outside. Liner materials can be PTFE with a coefficient of friction (COF) of 0.1, PTFE mixed with polyimide (COF of 0.3), or polyimide (COF of 0.5). Solutions to higher lubricity on the outside are PTFE, nylon, Pebax, and surface-treated silicones.

Extrumed and Dunn both produce Pebax tube with five different sequential durometers along the length. Dunn makes Pebax tube with 0.0025-in. wall thickness, 0.086-in. ID, and 0.0008-in. concentricity.

Since silicone is inherently porous and slightly sticky, it has to be coated if those traits aren’t desirable. Raumedic recently began sending silicone micro tube out for a secondary treatment that reportedly cuts surface stickiness by about 50%. To block both stickiness and porosity, silicone tubes can also be treated with parylene, a polymer applied by plasma treatment in a vacuum. It results in a COF comparable to PTFE.

Other tubing surface modifications use pharmaceutically functional molecules such as the anticoagulant Heprin. Polymer Technology Group, Berkeley, Calif., has modified micro-tube surfaces for eight years with its patented Surface Modifying End Group (SME) technology. This bonds a functional molecule to the ends of their TPU polymer chains, which have a special binding site. During and after extrusion, Heprin molecules migrate to the surface of the tube, reducing the risk that the tube will cause clotting.

Related Content

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreRead Next

Medical Tubing Coextrusion Brings A New Level of Care

Coextrusion is on the increase in tubing for medical uses, with more layers, more exotic materials, and much thinner walls. These require unprecedented levels of dimensional accuracy and flaw detection.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More