Melt Flow Rate Testing—Part 7

Here is why the melt flow test is not universal.

As useful as the melt flow rate (MFR) test can be, it is not universally applicable. Fundamentally, the test is intended to document differences in molecular weight. There are several factors that can make interpretation of the results difficult. The first involves polymers that do not initially degrade through chain scission, the chemical reaction by which the polymer chains become shorter.

PVC is a good example. Degradation in PVC begins with a process known as dehydrochlorination, an impressive term for the loss of hydrogen chloride. As the chlorine and hydrogen atoms separate from the polymer backbone, double bonds form, producing a change in color. But the oxidation that initiates chain scission may not begin until the loss of hydrogen chloride has proceeded to a significant degree. Therefore, the polymer may have undergone considerable modification without giving any evidence of a reduction in molecular weight.

A second problem is introduced by competing reactions that can increase and decrease the molecular weight of the polymer at the same time. Polymers such as nylons and polyesters can undergo a series of complex reactions that can produce this type of behavior.

The accompanying chart shows a comparison of two different PBT polyesters evaluated in the melt state over time. The melt viscosity of the materials was measured periodically using a capillary rheometer operating at a constant shear rate. One of the materials shows excellent stability and the viscosity changes very little over the duration of the test. However, the other material initially undergoes a rapid decrease in viscosity typical of chain scission followed by an increase in viscosity which has been attributed to a process of crosslinking promoted by the oxidation that caused the initial breakage of the polymer chains.

MFR tests performed on samples taken from various points along this time line would produce very different impressions of the condition of the polymer. A sample taken 20-25 minutes into the evaluation would show significant polymer degradation, a sample taken at 40 minutes would show no change, and a sample taken at 55 minutes would appear to show that the molecular weight had increased despite the fact that a part molded from material in this condition would be extremely brittle.

Impact-modified materials can produce a similar effect for the same reason. Butadiene rubber and EPDM rubber are both commonly used as impact modifiers. Both of these materials are capable of undergoing crosslinking when exposed to elevated temperatures. This can cause the MFR of these materials to actually decrease during processing, a behavior that is frequently observed in materials like ABS, PPE/HIPS blends, and impact-modified nylon.

Other constituents such as flame retardants can further complicate the response of the material to processing. In general, the more ingredients there are in the compound, the more difficult it becomes to make a straightforward interpretation of the MFR test results.

One excellent example of this principle is the influence of fillers. Because fillers do not melt at processing temperatures, they tend to increase the melt viscosity of a polymer. This increase is detectable at any shear rate, but it is more noticeable at low shear rates where the lack of orientation makes the filler particles or fibers much more resistant to flow. The problem with comparing the MFR results of pellets and parts when fillers are present pertains to the influence that the process has on the integrity of the filler. This is especially true of reinforcements such as glass fiber. We have established that processing can reduce the length of the polymer chain, and this is the primary area of interest when we perform MFR tests on molded parts and the related raw materials. But high-shear processes like injection molding also cause fiber length to be reduced, and this reduction also contributes to the change in the MFR measurement. Whenever MFR tests are performed on glass-filled materials, the measurement is a composite of the response from the polymer and the fiber. As the fiber content increases, the contributions from this ingredient become more important.

It is common for fiber lengths to be reduced by 50% during molding. These shorter fibers flow through the MFR tester more easily than the longer fibers in the original raw material. Therefore, it is not possible to apply the 40% rule discussed earlier to filled materials. Even at a 10% loading of glass fiber, the increase in MFR may be as high as 75% before we begin to have concerns about polymer degradation. By the time we get to a 30% glass content, the allowable MFR increase may be as great as 200%. The deviations between these benchmarks and the 40% value used to evaluate unfilled materials are designed to make allowances for the effect of typical fiber-length reduction on melt viscosity. The uncertainty becomes even greater when working with long glass fibers, while particulate fillers like talc may introduce a smaller variance from an unfilled product.

Ideally, we would not perform MFR tests on filled materials; we would instead employ solution-based measurements that work by dissolving the polymer in a solvent and removing the filler so that only the polymer is being considered. However, the MFR test is so accessible and easily performed that many suppliers of filled materials still use MFR as their quality-control parameter for average molecular weight. Therefore, it is useful to have a way of allowing for the contribution of fiber-length reduction on the MFR of a filled material.

Acetal, more commonly known these days as POM, presents a different problem. MFR is often used to distinguish between grades of this material. However, it has been shown that the MFR test is not useful for detecting process-induced polymer degradation in acetal/POM. In fact, even much more sophisticated techniques such as gel permeation chromatography (GPC) very often do not show any measurable change in the molecular weight (MW) of this polymer.

This is because the rate of MW reduction in acetals is so rapid at processing conditions that any polymer chains that begin to unzip reach a MW that is so low that they no longer influence the melt viscosity of the polymer. There is no significant amount of intermediate chain lengths in a degraded acetal. There are other analytical techniques that can detect degradation in POM, but typical MW determinations such as MFR, solution viscosity, and GPC are ineffective.

However, degradation of acetal that occurs in the solid state takes place slowly enough to produce a substantial amount of intermediate chain lengths. A good example is sustained exposure to hot water, particularly if the aqueous environment is mildly acidic. In this situation the reduction in average MW is gradual enough to produce the type of lower-MW constituents that the MFR test is designed to detect. In one case, an acetal homopolymer exhibited a 100% increase in MFR from as-molded parts to parts that had been immersed in 90 C water for 1000 hr.

While the vast majority of commercial thermoplastics list MFR on their data sheets, some materials make no mention of this property. In our next installment we will discuss the reasons for this and discuss some of the special problems related to measuring melt flow in nylons.

ABOUT THE AUTHOR

Michael Sepe is an independent materials and processing consultant based in Sedona, Ariz. with clients throughout North America, Europe, and Asia. He has more than 35 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

The Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

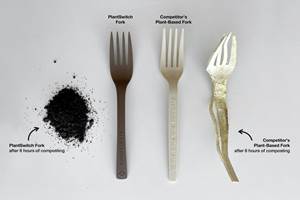

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MorePrices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreMelt Flow Rate Testing – Part 2

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

Read MoreMelt Flow Rate Testing—Part 3

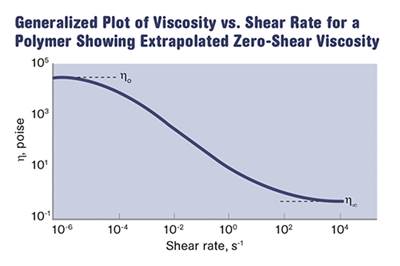

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read More

.jpg;width=70;height=70;mode=crop)