Micromolding Gets Bigger at Tessy Plastics

Micro parts are a tiny but fast-growing segment of its custom molding business, with potential to expand beyond the medical sector.

Medical molding is big at Tessy Plastics, accounting for about half its $250 million custom injection molding business (the other half being consumer products). And one of the fastest-growing segments of Tessy’s medical sector is micromolding of parts weighing as little as a few thousandths of a gram and measuring down to 0.063 x 0.038 in. It’s a specialized and challenging area of technology, but with the right machinery and tooling, Tessy is looking to apply its hard-won skills to micro parts for a wider range of markets.

EXPANDING IN MEDICAL

Founded in 1973, Tessy is still a family-owned firm, though now with over 900 employees in three plants. The headquarters facility in upstate Elbridge, N.Y., has grown to around 1 million ft2 in the last few years and houses over 200 injection machines. It also has a 75,000-ft2 plant with 40 presses in Lynchburg, Va., and 150,000 ft2 with 30 machines in Shanghai, China.

Tessy is a molder and contract manufacturer specializing in high-speed, multi-shot, and thin-wall injection molding, micromolding, and integrating molding with assembly, decorating, and testing operations. Tessy views itself as an engineering company that also injection molds and assembles parts. Over 60 engineers manage in-house R&D, prototyping, product design, tool design, flow simulation, and automation development.

Tessy’s commitment to medical markets is evident in its recent purchase of a 112,000-ft2 former Honeywell factory in nearby Skaneateles, N.Y., which will be dedicated to medical business. “We started the move there in December, but it will be a two-year process,” says Eric Frearson, v.p. of engineering and China operations. The move includes 25 injection presses, 10 automation cells, and toolmaking operations—all for one product line, a cartridge of laproscopic staples for minimally invasive surgery, with micromolded plastic “drivers” for the titanium staples. The product (for a major medical OEM) is already in production at the Elbridge plant. “We needed more space for the molding and assembly work for the cartridge devices” Frearson explains. There are up to 60 components in the surgical device. About 100 medical production workers will staff the new operation.

PULLED INTO MICROMOLDING

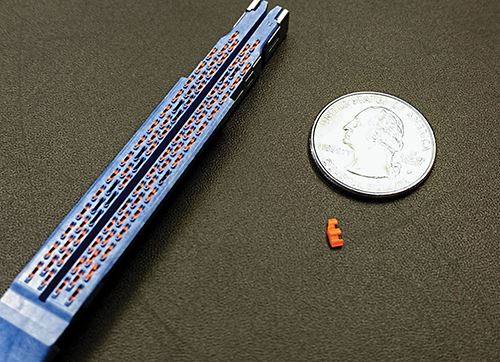

Tessy got into micromolding about six years ago, at customers’ request. “When we bid for and won the staple cartridge business, we looked at new ways to produce the tiny parts,” says Stafford Frearson, project engineer. The driver measures 0.0120 x 0.040 x 0.075 in. and weighs just 0.004 g. It’s molded in Ultem polyetherimide (PEI) from SABIC Innovative Plastics.

“We started out producing the parts on a conventional (30-ton) molding machine with a 16-cavity hot-runner system, molding 64 parts per shot,” recalls Stafford Frearson. “This worked, but not as well as we liked. The PEI material requires very high processing temperatures—720 F—and it was a challenge to produce consistent parts with the hot runner. Trying to maintain consistent heat and balance the system without burning the materials was difficult to do.”

Considering that the material costs around $20/lb and the parts required all-virgin material, Tessy needed to reduce waste and improve shot-to-shot consistency. So Tessy began looking for a specialized micromolding machine. According to Joe Raffa, v.p. and general manager, Tessy was interested in a unique micromolder developed by Battenfeld GmbH in Germany; but the machine builder was then going through a difficult period in its relationship with its private-equity owners and decided to discontinue the micromolding equipment.

Tessy then purchased three 15-ton, two-stage (screw-plunger) Sodick micromolders from Plustech, Inc. “They were fine,” says Raffa, but Tessy’s interest in the Battenfeld micromolders was reawakened when Wittmann GmbH of Austria purchased Battenfeld in 2008 and revived the micromolding line under the new MicroPower brand.

“Wittmann Battenfeld was working on redesigning its MicroPower machine for overall better form, fit, and function,” says Stafford Frearson. We liked the fact that Dr. Wittmann was committed to rebuilding the company and creating better machinery, so we decided to give the redesigned MicroPower a try.”

Tessy bought its first 5-metric-ton MicroPower machine four or five years ago to familiarize itself with the machine and its operation. Raffa notes that Tessy liked the MicroPower for the speed of its rotary mold table, compact footprint, and its integrated parts-inspection options, which were not available from other vendors, and the commitment by Wittmann to develop other options.

Tessy was asked to quote more and more micro projects, so it bought two more 5-m.t. MicroPower presses, and two more—the most recently purchased machine was brought on line last month. All of the machines run in Class 10,000 and Class 100,000 clean rooms. Most are located inside a clean-room structure, but some operate as self-contained clean-room cells.

Tessy now molds the surgical components in an automated cell that ties two MicroPower presses with one automation system. Raffa says this was done to make best use of the high throughput capacity of the automation system. The staple drivers are now made on smaller molds with five cavities and four pieces per cavity. The hot runner is eliminated in favor of direct gating into sub-gated cavities. Parts are automatically degated in the mold. The MicroPower injection machines have integrated SCARA robots and camera inspection systems, and they are serviced by Wittmann dryers, feeders, and temperature-control units.

As compared with production on the conventional injection press with the 16-cavity hot runner, Tessy has seen almost 20% less material waste, saving almost $1 million per year. Add to that faster cycle times and better shot-to-shot consistency with the screw/plunger injection system, which results in fewer rejects, and the overall cost savings have been substantial.

Other micro parts now being molded on Wittmann Battenfeld MicroPower machines include an insulator for a printed circuit board. Tessy molds metal inserts into the PEI insulator, which is then soldered onto the PCB. The newest application is a polycarbonate part for eye micro-surgery, which also involves overmolding plastic onto a metal insert.

“There are many challenges to molding micro parts,” says Stafford Frearson. “Micro parts and molds are highly specialized and not everyone can do it.”

Raffa seconds that notion. Shot-size control and accuracy are primary concerns for the molding operation, he says. Finding tool shops capable of making highly accurate molds with tiny features is another. “Everything needs to be more precise,” Raffa notes. Tessy has found a couple of U.S. moldmakers with the requisite skills, but Raffa declined to name them.

The automated cell with paired MicroPower machines will be moving to the new Skaneateles plant. Given the rapid growth of Tessy’s micromolding business, Raffa foresees extending such operations to its other plants—even China. “It’s ready for it,” affirms Raffa.

Tessy is also looking for micromolding business beyond medical markets. Raffa sees opportunities in electronics and electromechanical devices: “Everything is getting smaller and smaller.”

What enhancements would Tessy like to see in micromolding technology? “More speed, accuracy, and consistency,” answers Raffa. He says Tessy may buy more MicroPower machines in the future but is looking at other vendors, too. “Competition is good for the industry. We’ll go with whoever offers the latest and best technology.” He says Wittmann Battenfeld has the edge today, partly because its machines lends themselves to manufacturing cells. “We like to integrate machines directly into automation.”

There are other advantages, too. Matt Willsey, Tessy senior technician in charge of running the MicroPower machines, likes the web-enabled remote services for the B6 control system on the machines: “We are able to contact Wittmann Battenfeld anytime we have a question or an issue, and they respond immediately. On a couple of occasions they have connected remotely through their web services and taken control of the machine so they can see exactly what’s going on and recommend solutions.” On applications as critical as these, that kind of service is essential, he says.

Tessy Plastics has broad experience with Wittmann Battenfeld. Tessy uses over 25 of that vendor’s robots, as well as dryers, granulators, and TCUs. Tessy also uses Wittmann Battenfeld’s M7.3 central material-handling system, equipped with the largest Codemax RFID coupling station in the U.S., to supply a wide variety of materials to the molding machines at rates up to 30,000 lb/hr.

Related Content

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreAllegheny Performance Plastics to Enter Health Care Sector

The custom molder has secured multiple projects in health care and will be adding cleanroom and white-room spaces, as well as injection molding machines, in support.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More