Three Straight Years of Record Results for Arburg

Arburg marked a third straight year of record turnover with growing contributions from Asia, as well as its newer large-tonnage and all-electric machine offerings.

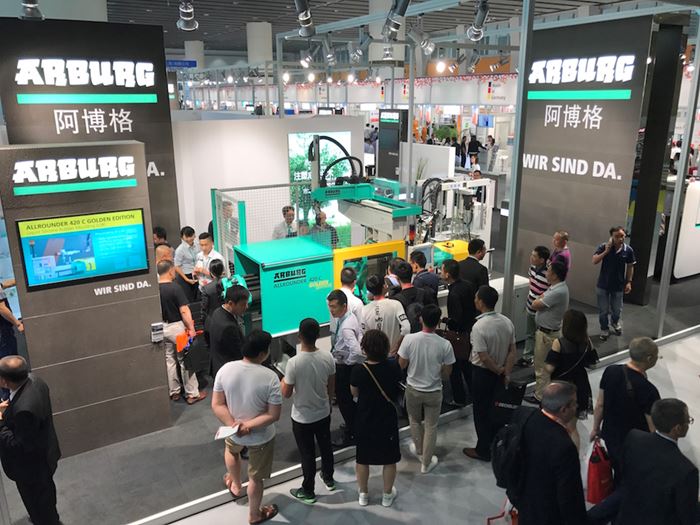

Gerhard Böhm, managing director sales for Arburg GmbH & Co. KG (Lossburg, Germany; Arburg Inc., Rocky Hill, Conn.), used Chinaplas 2017 (May 16-19; Guangzhou) to share results from the company’s most recently completed fiscal year, which saw it generate consolidated revenue of Euro 630 million ($706 million).

Böhm said that the share of total sales garnered from all-electric machines had grown to 27%, rising since the launch of its Golden Electric machine series in the spring of 2016. Like the previously launched Golden hydraulic series, the Golden Electric features more standardized components as a means to lower its price point and create an “entry level” all-electric molding machine.

Hybrid machines’ share of sales also grew, reaching 16%, as did machines with clamp forces above 2500 kN (250 tons), with those now accounting for 24% of sales and “steadily increasing in recent years”, according to Böhm. The company’s interest in larger tonnage presses was on display at K 2016. There, Arburg introduced an all new machine and size—the Allrounder 1120 H—its largest press to date with 650-metric-tons of clamp force.

So-called turnkey solutions, or machines equipped with automation and other technologies, accounted for 17% of sales. Böhm said the interest in robotics paired with presses extended to Chinaplas, where all its exhibits were automated.

25 Years in China

Starting in Hong Kong in 1992, 2017 marks 25 years of a presence in China for Arburg, which opened further subisidiaries in Shanghai in 2004 and Shenzhen in 2006. Both those locations have 200-m2 (more than 2000-ft2) showrooms that can accommodate up to seven Allrounders. Arburg also established a 1500-m2 (more than 16,000-ft2) warehouse in Shanghai that it says helps significantly reduce delivery times for presses.

Arburg has installed service technicians and sales along the entire “plastic belt” of the Pacific coast, as well as in country’s center around Chengdu. The company added that 30% of employees in China are in service and after sales.

Zhao Tong, president of Arburg’s Chinese operation, said that Arburg will mark its silver anniversary with special events on July 7 in Shanghai and September 22nd in Shenzhen. In addition, machines bought in China will come with a “special service package”. Tong discussed a shift in Arburg’s local customer base over the last quarter century.

“In the early years, [Arburg] worked with globally operating large-scale companies, but this has changed significantly,” Tong said. “We are delighted that more local injection molding companies take advantage of our machines.”

High-End Machines for High-End Parts

Despite the introduction of its more economical Golden series machines to the market, Arburg is still offering a premium press to a market with a reputation for seeking the lowest cost equipment. “In every market you have certain challenges,” Tong said. “The Chinese market is quite price sensitive, and we come from Germany; we belong to the high end, but today we’re also quite well accepted by Chinese customers.”

Böhm elaborated further. “China is price sensitive, but not for 100% of parts,” Böhm said. “You have the same situation you face all over the world; if you need a high-end part, you need a high-end machine.”

Böhm, Tong and Andrea Carta, Arburg’s director of overseas sales, all see growth in the need to product high-end parts. “We see the trend that the Chinese market has more and more increased demand in high-end production,” Tong said, adding that China’s government-lead Made in China 2025 push will only increase the growth of technical molding. “Made in China 2025 requires more precision in production and more efficiency.”

“We don’t see a slow down in plastics,” Carta said. “We do see a shift from low-value to high-value molding; manufacturers here want to upgrade their technology.” Carta added that the last two years have been the best two years in Arburg’s history in China, and that 2017 has already started ahead of 2016’s pace.

Related Content

Injection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More