Articles

Free Guidance on Molding Resins

Mobile Specs app and website provide processing parameters on thousands of resins … at no cost.

Read MoreIt’s a Connected World Now for Pumps, Valves & Drives, Too

New connectivity products from Bosch Rexroth permit digital monitoring of hydraulic systems for remote diagnostics and predictive maintenance.

Read MoreSwitch to Centralized Vacuum Supply Saves Molder Energy, Boosts Production

Less maintenance means more time for processing, thanks to elimination of vacuum pumps at each press.

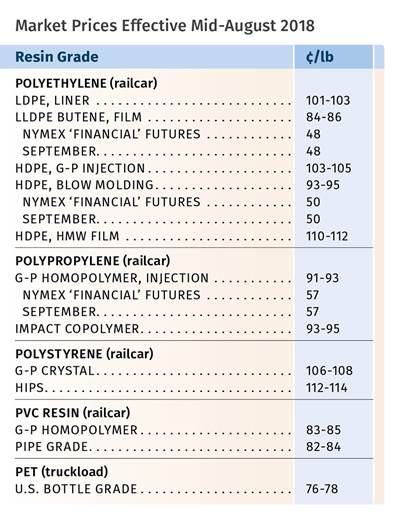

Read MorePrices Flat for PE, PVC; Down for PS; Up for PP, PET

Contrary feedstock and demand trends lead to divergent pricing behavior.

Read MoreReducing Low-Level Background Gels in PE Film

While considered acceptable in many cases, they need not be tolerated and are usually attributable to minor screw-design flaws. Here’s some advice on what to do about them.

Read MorePellet to Gate Control: The Value of a Holistic View of Melt Management

Molders tend to think about the elements of a melt-delivery system, from screw to hot-runner gate, in isolation from each other. But taking an integrated view of the whole system can have big consequences for cycle time, part quality, scrap rates, and energy consumption.

Read MoreAccredo’s Credo: Designed for Sustainability, Built for Success

In fewer than 10 years, Accredo Packaging has developed innovative packaging solutions—including the first-ever all-PE barrier standup pouch—while maintaining its commitment to being ‘green.’

Read More5 Ways Resin Conveying Systems Are Getting Smarter, Easier to Maintain

These five short videos provide a snapshot of what’s going on with the technologies that drive and control plastics resin conveying systems and provide unmatched operational visibility. Plastics processors will benefit from conveying systems that are more reliable, flexible and expandable to meet your plant’s specific needs.

Read MoreTooling: Why Ejector Pins Break And How to Prevent It, Part 2

Here’s the when and how to reduce the unsupported length of pins.

Read MoreInjection Molding: Is There a ‘Most-Important’ Process Parameter?

A case can be made for multiple variables—fill balance, fill time, injection pressure, cavity pressure—as most important. But there is something else altogether that is essential to successful injection molding.

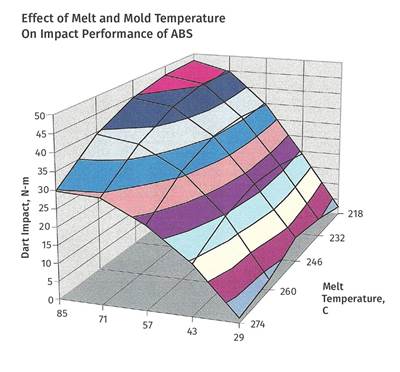

Read MoreA Processor’s Most Important Job, Part 8: Molded-In Stress

How processing adjustments can control molded-in stress.

Read MoreMarket Trends in Polymer Additive Manufacturing

Unlike the BetaMax/VHS technology debate, all the established polymer print technologies have a viable long-term role to play in the 3D-printing industry.

Read More