Articles

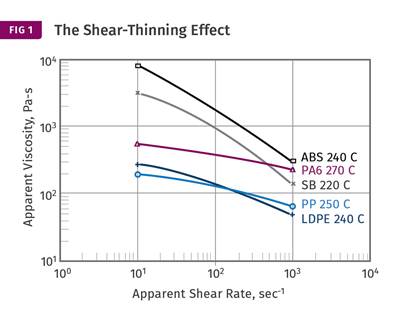

Finagling the Flow: Making Viscosity Work For You In Molding

Viscosity represents a broad concept with huge effects on any efforts to standardize an injection molding process. It is also one of the most important weapons in a molder’s arsenal for making process changes.

Read MoreEvonik Shares Results of its Post-it Note Campaign at K 2016

Environmental protection and sustainability led visitors’ comments.

Read MoreAutomation Cuts Production Time For LED Lighting Units by 89%

Robot-assisted overmolding helps Swiss company compete with low-wage countries.

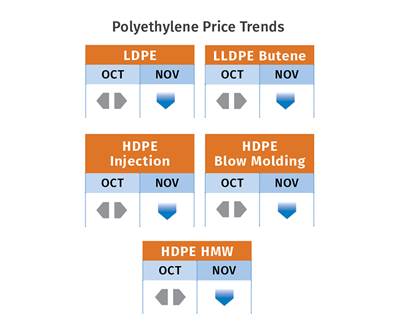

Read MorePolyolefin Prices Drop; Ditto for PET

PE, PP, PET prices head down, PS and PVC flat for now.

Read MoreTake These Steps To Maintain Efficiency Of Your IBC

The overall performance of a blown film line depends on a properly tuned and maintained IBC control system. Follow these preventive-maintenance tips to keep your system running smoothly.

Read MoreService & Response Drive Growth of Custom Compounder

Lanier Color has experienced an eightfold increase in business since 2000. Its focus on technical support and customer service help explain why.

Read MoreThanks to This Material, There's No Hard Coating Needed

New additive that improves scratch/mar resistance in molded & extruded parts.

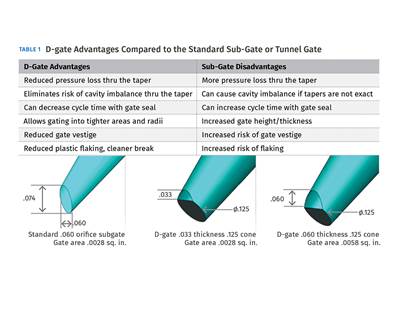

Read MoreGating Revisited

An overlooked factor in injection molding has outsize influence on the process and part quality.

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

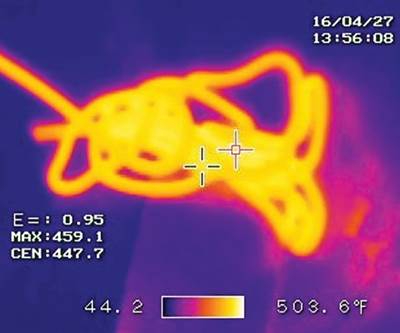

Read MoreUnraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

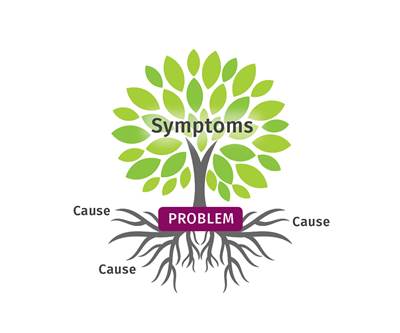

Read MoreFinding Root Causes of a Material Problem

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read More