Articles

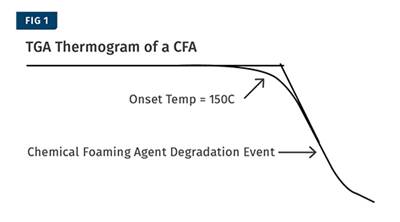

How Characterizing and Modeling Chemical Foaming Agents Can Help Your Process

Knowing ahead of time what will happen when your CFA produces gas can help you design or improve your process to boost quality and cost effectiveness.

Read MoreOvercome Typical Challenges in LSR Molding

Here’s a quick overview of basic mold and machine factors behind common LSR molding headaches and how to avoid them.

Read MoreHow to Dry PET for Container Applications

PET is extremely hygroscopic, highly moisture sensitive, and one of the toughest challenges to dry. Here are the basic principles of doing it right for rigid packaging applications

Read MoreOn Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreWhy Processors Are Rediscovering Liquid Colorants

In extrusion, injection, and blow molding, liquid color is enjoying something of a renaissance. Cost is one reason, but advances in pigments, carriers, delivery systems, and innovative service programs have played a role too.

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

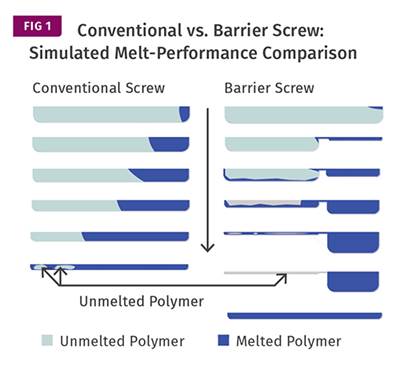

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read MoreHigh-Pressure Water: A New Concept for Screw Cleaning

Everyone in a molding plant is on the same page for screw cleaning: Avoid pulling it until there is no alternative. Here are ways for dealing with the inevitable, including an altogether new technique.

Read MoreThe Mystery of Physical Aging, Part 2: Slow Down Aging

Dimensional and property changes depend on the size of the part, molecular weight of the resin, and processing conditions.

Read MoreTaiwan’s ‘Time is Coming’ For All-Electric Machines

Taiwan’s plastics machinery market is a player on the global stage, except for one segment—all-electric machines. The recent Taipei Plas show suggests that’s about to change.

Read MoreKey Themes from the Fakuma Show

Servo-hydraulics, servo sprue pickers, electronic water-flow monitoring/control, and exotic multi-process cells were the headliners in Friedrichshafen.

Read MoreDispenser Molder Opens New Plant in Illinois

Worldwide Dispensers is up and running in Bolingbrook with 10 injection molding machines ranging in clamp force from 25 to 700 tons.

Read More