Articles

What’s the Deal With High-Speed Extruders?

If we are talking about extruder screw speed, how about 1800 rpm? That’s how fast some extruders are running today.

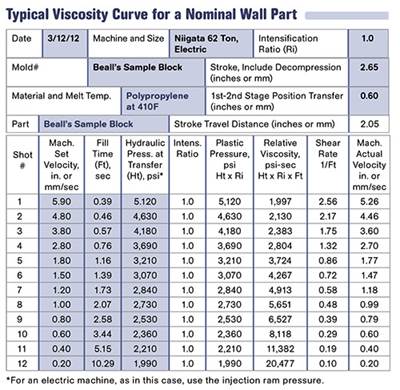

Read MoreUnderstanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreBlow Molding at NPE: Pushing the Envelope in Speed, Flexibility, Energy Savings

New models of blow molding machines at the show were dominated by wheel machines and stretch-blow systems.

Read MoreVent Bleed

Poor screw design is usually to blame for vent bleed on a two-stage vented extruder. But it may not be the culprit.

Read MoreAutomotive drives plastics processing

Fifteen million units is my personal benchmark for annual U.S. auto sales.

Read MoreScrew Rebuilding

Screw flight diameter clearance has a significant impact on the performance of your screws.

Read MoreSolving Splay

Moisture and shear are the two primary causes of splay on an injection molded part.

Read MorePoor Solids Conveying?

Molders quite often call me and say their screw is “windmilling” or isn’t picking up the material.

Read MoreHigh-Flow Nylon Carries the Load in New Fork-Lift Truck

WEB EXCLUSIVE: New I-ton hand pallet truck (HPT) from Lifter S.r.l. of Italy (U.S. office in Marietta, Ga.) is the first pallet truck in the world made of nonmetallic material.

Read MoreAnother Big Backer for Biobased PEF Bottles

WEB EXCLUSIVE: Avantium in the Netherlands has signed its second major partnership for using its new catalytic process to convert plant sugars into furanic precursors for a new polyester bottle resin.

Read MoreChevron Phillips Announces PE Plant Location

WEB EXCLUSIVE: Chevron Phillips Chemical Co., The Woodlands, Tex., has chosen a site near its Sweeny facility in Old Ocean, Tex., for two new polyethylene plants to accompany a planned 3.3-billion-lb/yr ethane cracker at Cedar Bayou in Baytown, Tex.

Read MoreFoaming Developments Aplenty in Extrusion

At NPE2012, Macro Engineering and Technology, Mississauga, Ont., launched new technology to extrude foamed films in what it describes as an “environmentally friendly process” that uses inert gas as the foaming agent.

Read More