Articles

Powder Injection Molding Helps PTI Thrive in Specialties

“We like challenges. We like to do things that other people are scared to do.”

Read MoreUV Cure Solves LSR Processing Challenges

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

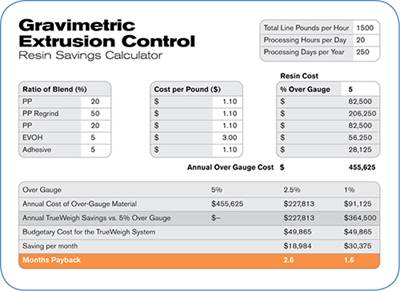

Read MoreHow Gravimetric Control Systems Pay Off in Blow Molding

Gravimetric control systems offer blow molders improvements in processing efficiencies above and beyond their ability to regulate resin usage.

Read MoreMolder Slashes Energy Cost With Move to Desiccant Drying

Yes there are still molders drying with tray ovens. But this processor replaced the last few it had and has reaped some impressive energy-savings benefits.

Read MoreSoothing a Temperamental Process To Make Better Bottles

Careful choices of machines, tools and operators are critical to tame the process to produce high-quality bottles consistently.

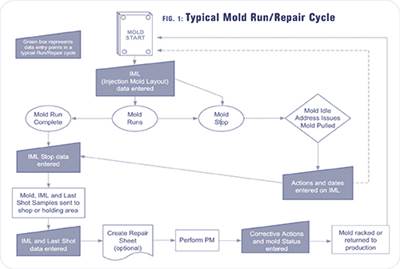

Read MoreThe Value of 20 Bits of Data

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

Read MoreWater, Oil, Air, or None?

There is no one 'best' barrel cooling medium, but there seems to be a shift in the industry toward air cooling.

Read MoreGetting Good Data from DOE

How do you know what process variables control a part’s dimensions or other properties? A properly conducted DOE is the answer—but incorrect procedure will yield useless data.

Read MoreWorking with Color Concentrates

Industry needs more development of enhanced-mixing screws.

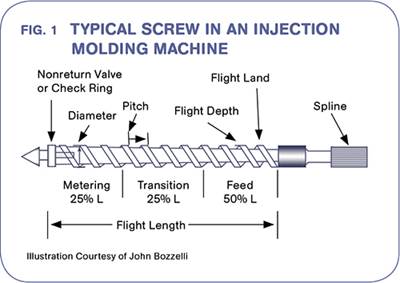

Read MoreGet Better Mixing From Your Injection Molding Screw

In the injection molding process when using standard general-purpose, single-stage screws, operators will typically increase the back pressure whenever better mixing is needed.

Read MoreInjection Molding Virgin vs. Regrind

Most processing operations generate regrind. Therefore, it is necessary to be able to reprocess the regrind back into the part.

Read More