Articles

Sharpen Your Pencils: Participate In ‘Top Shops' Benchmarking Survey

The free, anonymous survey of injection molders is open for responses, and all shops that complete the questionnaire will receive a customized report of the results. Honorees also will be recognized in the magazine.

Read MoreEnergy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.

Read MoreJanuary’s Most-Viewed Stories

Readers sought out sustainability related topics in January, along with TCU and extruder vent-design tips, new drying technology, prettier pellets and more.

Read MoreSustainable Ionomer Copolymers to Play Role in Major Perfume and Cosmetics Packaging Collaboration

Dow and LVMH to collaborate to improve sustainable packaging across several well-known perfume and cosmetics brands

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MorePlastics and the Joy of Chemistry

A Public Broadcasting program revels in the achievements of polymer chemistry while also warning of the problems that come with its benefits.

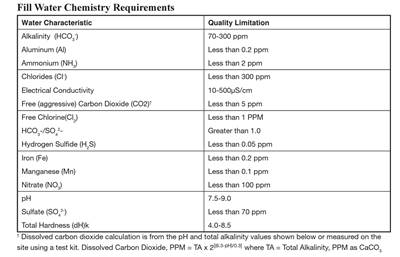

Read MoreTroubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

Read MoreWhat Type of Recycling Technology Works the Best? It Depends

NREL scientists describe a framework for comparing recycling technologies.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

WatchWhat Stories Would Your Most Challenging Injection Molded Part Tell?

Time is running out to enter Plastics Technology’s Hot Shot’s Injection Molded Parts Competition — share your company’s capabilities via its greatest molding challenges.

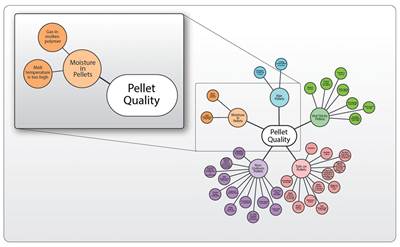

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read More