Articles

Waste Plastics Must D-I-E

New research publications describe dehydrogenation, isomerization, ethenolysis as a pathway for polyethylene recycling.

Read MoreThe Secret to Molding with PCR: Don’t Fear Variation – Embrace It!

“Embrace variation” – That contradicts all normal thinking about processing plastics. But the only thing that’s “normal” about recycled plastics is variability, and that requires a processing philosophy that assumes variation and is geared to deal with it.

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide Blends

PPO was a promising new high-performance thermoplastic, but it could be made useful only by mixing it with a humble commodity resin.

Read MoreSPE’s Automotive Division Names 2022 Hall of Fame Winner

First mold-in color weatherable grille used on the 1987 VW Golf to be celebrated at the 51st annual SPE Automotive Innovation Awards Competition & Gala.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreThoughts About Venice – and Recycling

The gleaming city on the Adriatic is held up by uncountable numbers of wooden pilings. Is that a viable model for the future of plastics recycling?

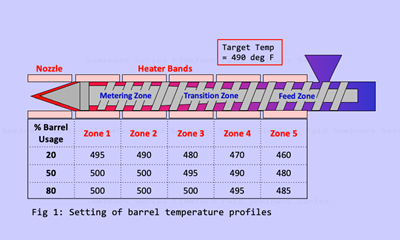

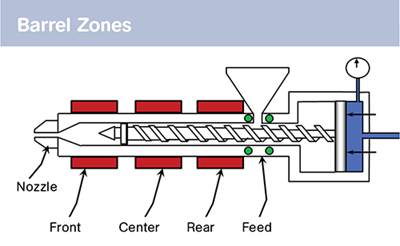

Read MoreMelt Preparation Part 1: Melt Temperature Optimization

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

Read MoreBusiness Leaders Discuss the Challenges Facing Recycling

At a virtual event, business leaders discussed the recycled plastic demand gap and other challenges.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

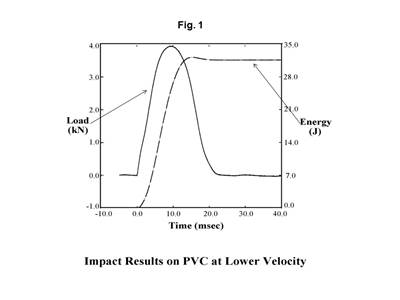

WatchThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

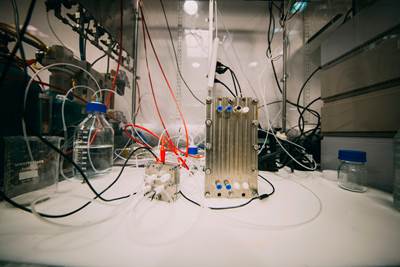

Read MoreNovel Catalyst for Converting Carbon from Hard-to-Abate Sectors

RenewCo2’s technology can transform carbon into feedstock for carbon-negative, plastics monomers, such as MEG and ethanol.

Read More