CFRTP Composites Set to Grow at Expanded Pace Over Next 10 Years

Market research firm Fact.MR projects an annual growth of over 8% for continuous fiber-reinforced thermoplastic composites.

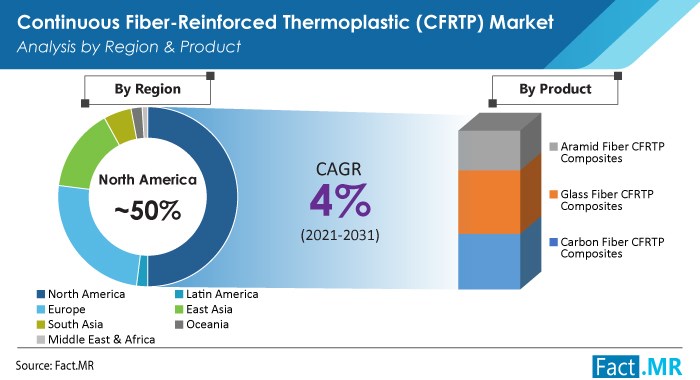

The market for continuous fiber-reinforced thermoplastic (CFRTP) composites has grown annually at about 4% within the last five years. Moreover, the future outlook appears to be even more robust according to a study from market research and competitive intelligence provide Fact.MR (U.S. office in Rockville, Md.). The new report, Continuous Fiber-Reinforced Thermoplastic Composites—Consumption Analysis from 2016-2020 vs. Future Market Outlook for 2021-2031, projects annual growth of over 8% for the ten-year period.

Continuous fiber-reinforced thermoplastic composite manufacturers are actively cooperating with their partners to promote their business. Although carbon fiber and glass fiber thermoplastic composites account for a dominant share in the market, due to their own distinctive characteristics, demand for CFRTP composites market has been fast increasing.

CFRTP composites are durable and lightweight, providing significant weight reduction and strength & stiffness to end products. Having multiple advantages such as high strength-to-weight ratio, excellent load carrying ability, low-coefficient of thermal expansion, and resistance to deformation and cracks, CFRTP composites are used in many end-use industries including automotive, aerospace, and electronics. Says one Fact.MR senior analyst,“Augmenting preference for lightweight materials with constant technological breakthroughs will pave the way for expansion of the continuous fiber-reinforced thermoplastic composites industry over the years to come.”

Here are some key takeaways of this report:

▪ Rising adoption of environment-friendly vehicles in particular are one demand driver. As fuel efficiency depends upon the weight of a vehicle, there is increase in requirement for lightweight materials, which is anticipated to drive demand for CFRTP composites.

Meanwhile, electric vehicles (EVs) have been gaining a lot of traction in recent years. CFRTP composites have high strength and contribute significantly to vehicle weight reduction, and are extremely useful in the manufacture of EV parts. According to the study, as the market for electric vehicles grows, increase in consumer awareness towards pollution-free and efficient vehicles is further fostering demand for lightweight vehicles, which, in turn, is driving demand for CFRTP composites in the market.

▪ North America dominates this market with a share of over 50%. This region is expected to remain the largest regional market due to the presence of leading part fabricators, and is also expected to have the highest growth because of rising penetration of CFRTP composites in major end-use industries. The low weight and high tensile strength of composites increase fuel efficiency, reduce maintenance costs, and allow OEMs to comply with stringent environmental regulations in North America. There has been increasing production of single-aisle airplanes by Boeing in North America, which is likely to drive the market in the region.

▪ Glass fiber composites accounted for a market share of around 40% in 2020, and are expected to experience significant growth on account of their low cost, simple fabrication methods, and ability to process with different resins.

Glass fiber are used mostly in electronics, construction, transportation, and other industries. However, due to COVID-19, these industries saw a drop in CFRTP composite demand due to decline in aircraft deliveries, and reduction in number of wind energy installations as well as automobile and electronics goods sales. Demand in North America is expected to gain momentum with the recovery of these end-use industries.

▪ Major players with a prominent share in the market are focusing on expanding their customer base. Included are Lanxess AG which in 2018 announced a new thermoplastic specialty compounds facility in Krefeld-Uerdingen, Germany. This will increase the capacity of the facility by over 22 million lbs/yr. It will help the company cater to demand for nylon-based compounds.

Avient (formerly Polyone) launched new thermoplastic composite products at Chinaplas 2019. Complet LFT formulations are thermoplastic composites with PEEK and PP as a base resin, to meet highly demanding design and performance requirements.

Related Content

Prices of PE, PP, PS, PVC Drop

Generally, a bottoming-out appears to be the projected pricing trajectory.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MoreFirst Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.

Read MoreFundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More