Continuous And Long Fiber Thermoplastic Composites In Automotive

Thermoplastic composites represent a new class of structural parts for automotive and a new opportunity for injection and compression molders.

Thermoplastic composites represent a new class of structural parts for automotive and a new opportunity for injection and compression molders. Machinery systems are still evolving, but the latest advances in automation, speed, energy efficiency, and materials efficiency will be presented at the first-ever Thermoplastic Composites Conference for Automotive next month in Novi, Mich.

Organized by the editors of Plastics Technology and sister publications Composites Technology, High-Performance Composites, and Automotive Design and Production, this event will present 17 speakers in a day and a half of technical presentations, co-located with the amerimold 2014 expo, also sponsored by Gardner Business Media, parent of Plastics Technology. The conference will comprise four sessions on Materials and Applications, Machinery Systems, Processes, and Continuous and Long Fiber Thermoplastic Composites in Automotive.

Here’s a brief look of Session IV, with presentations from a major engineering thermoplastic resins supplier, a prominent compounder of high-performance thermoplastics, and a pioneer of continuous fiber reinforced thermoplastics recycling of automotive production waste.

“Hydrogen Storage for Automotive Using Thermoplastic Composites” by Michael Ruby, global composites business manager, engineered materials at Celanese, will address the progress made in the development of a monolithic thermoplastic composite for a hydrogen storage vessel based on the company’s POM (aka, acetal) resin and unidirectional continuous-strand, carbon fiber-reinforced thermoplastic tape with POM matrix.

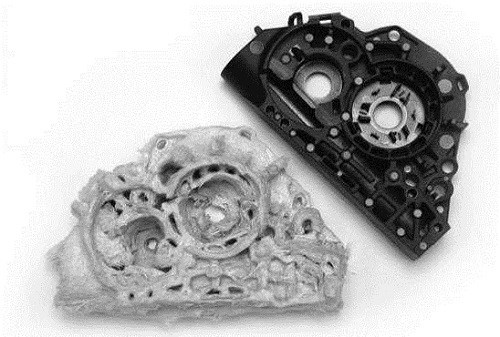

“Very Long Fiber Thermoplastic Composites for Automotive Applications” by Nolan Krause, application development engineer at RTP Company, will discuss advantages of long fiber glass as reinforcement in PP and nylon, for applications such as this seat-belt tensioner housing, along with molding considerations and guidelines.

“Closing the Loop of Automotive Carbon Fiber Waste: Reclaiming the Fibers and Applications in Long-Fiber and Short-Fiber Processes” by Alex Edge, sales & business development manager at ELG Carbon Fibre Ltd., will address strides made by his company--which claims to have the world’s first commercial-scale continuous recycled carbon fiber operation, including reclaiming and processing long carbon fibers in new automotive applications.

For details on the conference, visit here. For details on the amerimold show and conference, visit here.

Related Content

-

What is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

-

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.