Did I Say Mexico Was Hot?

On Jan. 2, I wrote that Mexico was benefiting from the trend of “reshoring” manufacturing jobs from Asia to North America. New evidence of that trend came in today from PolyOne Corp.

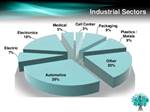

On Jan. 2, I wrote that Mexico was benefiting from the trend of “reshoring” manufacturing jobs from Asia to North America. New evidence of that trend came in today from PolyOne Corp., Cleveland, which is realigning some assets it acquired last year as part of Spartech. Those assets are located primarily in Ramos, Mexico, and will now operate within PolyOne’s Producer Services business unit, which provides contract compounding services to resin producers, processors, and OEMs. Here’s the kicker: “Our multinational customers are increasingly concentrating production in North America and often choose Mexico as a strategic location,” said Robert M. Patterson, PolyOne executive v.p. and CEO. “Under the leadership of our Producer Services team located in Seabrook, Texas, we look forward to expanding our capabilities in Mexico with improved customer service, quality, and delivery.”

As I noted in my earlier post, rising labor and other costs in China are making Mexico increasingly cost-competitive—not to mention it’s being on the same side of the ocean as customers in the U.S. and Canada.

Related Content

-

The Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

-

Small Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.