EVCO Plastics Gears Up To Mold Coronavirus Test Kits

The firm has added shifts, reassigned people and injection machines—and is buying new ones—in a crash program to mold and assemble COVID-19 test kits.

EVCO Plastics is a global custom injection molder with nine plants and 210 machines devoted to a wide range of markets. Its medical business, in particular, is humming with new projects aimed at combatting the coronavirus pandemic. The company has three plants and a Tech Center at its headquarters location in DeForest, Wis. Both people and machines were transferred from some of these to the EVCO Plastics MED (Medical and Electronic Devices) Plant, which has an ISO Class 8/Class 100,000 clean room, where the bulk of these COVID-19 related projects are underway. At the end of May, EVCO had 17 machines molding COVID-19 related parts, and orders were still increasing.

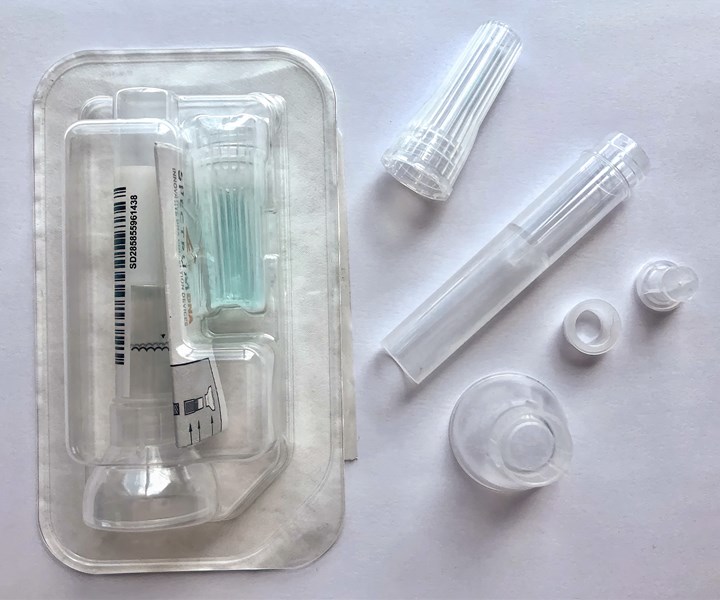

New saliva-based coronavirus test kit will be produced 24/7 in a five-machine cell with automated assembly, filling, sealing, weighing, labeling and packaging in a thermoformed tray.

“We’ve been doing DNA test kits, used for criminal investigations and consumer ancestry analyses, for some time,” says EVCO president Dale Evans. “So we repurposed some resources from that to COVID-19 test components.”

Since March, EVCO MED has had three machines devoted to making the three main components of coronavirus nasal-swab kits. They have been running 24/7 instead of the 24/5 schedule used for previous work.

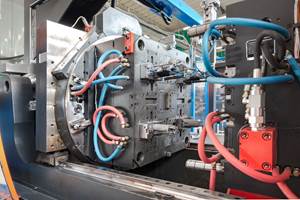

Production cell with one of three presses for coronavirus nasal-swab test kits stepped up from 24/5 to 24/7 production.

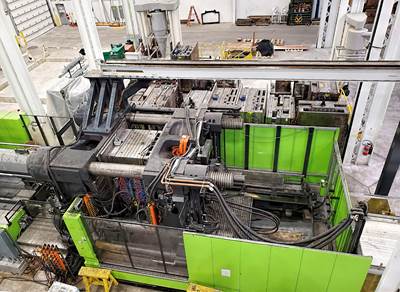

Another press has been molding parts 24/5 for a newer saliva-based test; that project migrated to commercial production last month with the startup of a five-machine cell molding and assembling five parts for the newer test kit. Those presses are running 24/7 molding parts of medical-grade, clarified PP in 16 cavities. One of those machines is a new 130-ton Engel press that was bought for this job. Initially, the cell utilizes manual assembly, but the customer designed and built custom automation to assemble the five parts, fill the assembly with test fluid, seal it, weigh it to confirm the degree of fill, then apply a barcode label, load kits into a thermoformed tray, and apply a Tyvek seal. Automation will triple output to one finished kit per second. Evans figures that cell will require 40 people (10 per shift), some of them transferred from other operations, and some of them new hires. Meanwhile, tooling is being built for another cell of five machines, some shifted from other buildings, including two presses from the Tech Center, and some new purchases.

EVCO’s tooling group worked through a weekend to design a two-cavity injection mold for PP head bands for thermoformed face shields and got into production in eight days.

And that’s not all. EVCO designed and molds PP head bands for thermoformed PET face shields sold by two customers. “Our tooling group worked through a weekend to design a two-cavity mold, which we got into production in eight days. Two such molds are now running.

To prepare EVCO’s facilities for operations in the age of coronavirus, “We cleaned and cleaned and cleaned some more,” says Evans. “We buy alcohol by the drum to formulate our own cleaning solution and disinfectant. We have hand sanitizer all over the place. Employees get their temperature scanned and wash their hands when they enter the plant. They wear masks everywhere—not just in the clean room. We employ social distancing. All this we learned first at our Chinese plant.”

In addition, EVCO has adopted handheld UV lights to disinfect machine control panels. Dale uses one in his office for his computer keyboard and phone.

Related Content

Molder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreSecondary Injection Unit Provides Primary Benefits for Molder

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Read MoreRead Next

More Milestones for EVCO Plastics

Custom injection molder is adding floorspace, machine capacity, and contract manufacturing capabilities at multiple plants in the U.S. and Mexico.

Read MoreEVCO Plastics at 50: Still Thinking Big

In its first half-century, EVCO Plastics has grown from one half-ounce injection machine in a basement to a $130 million company with 148 presses and 900 employees at nine plants in the U.S., Mexico, and China.

Read MoreFull Plate of New Technologies on the Table at EVCO Plastics

A new low-pressure molding process, 3D printing of production parts and prototype tooling, collaborative robots, and process monitoring with automatic QC are all on the menu.

Read More