Thermoplastics in Expanded Automotive Applications

From all angles, new thermoplastic solutions redefine ‘performance’.

Take a look at the cover story of PT’s upcoming June issue in which this editor took a stab at summarizing recent innovations in thermoplastics for automotive. A daunting task, since there are so many potential applications for thermoplastics, whether in a car’s interior, under its hood, and a good deal of what’s visible on the exterior. Not to mention innumerable plastic components that don’t you don’t see in the powertrain, chassis, and elsewhere.

We asked materials suppliers that have been among the leaders in the development of automotive applications to weigh in on what they see as the areas of an automobile experiencing the most dramatic developments in thermoplastic materials offerings.

Lightweighting for fuel efficiency has been a dominant theme, however, there are many other performance requirements that drive materials developments, such as resistance to heat, wear, sunlight, and fuels and chemicals. In other cases, the goal is improved processability to enhance quality and reduce manufacturing costs.

Not all that was discussed could be included due to space limitations, and I thought it worthwhile to describe some key highlights that were left out. Here they are by category as identified by the contributing suppliers:

Interior & Ambient Lighting

● Interior and ambient lighting is area consistent with the overall demand for high-quality auto interiors, according to Jerry Majur new business development manager at Trinseo. He notes that versatility in lighting is now commonplace with the advent of LED technology.

LEDs allow considerable flexibility in design and plastics enable manufacturers to take advantage of the technology’s benefits. From lighting that illuminates a display, wraps around a dashboard, or outlines a door panel—these configurations were never as possible or affordable.

The Trinseo automotive team is seeing more demand from customers in this area. “We actually have a dedicated lighting group as part of our performance plastics/consumer essential markets business and have been able to leverage the experiences we’ve had with some of the largest global lighting OEMs. In lighting, it’s all about balancing performance properties to ensure the right amount of light is emitted to produce the desired effect.”

● A. Schulman’s Frank Roederer cited the trend to “forward-lighting technology” for reflectors and the requirements shifting to LED technology. “In the past, the technology driver was the need for heat-resistant materials for headlight reflectors; however, now the need centers on dimensional stabilities as these reflectors are getting increasingly smaller.” Over the years, A. Schulman has supplied plating ABS and high-heat ASA for automotive light housing.

“We mainly supply for the RCL (rear combination lamp), CHMSL (center high mount stop lamp) and LP (license plate) pocket light housing applications,” says Roederer. He also mentioned a new light diffuse weatherable polymer supplied for LED lighting—Transparent Weatherable Polymer ASA TWP502, which is compatible with such secondary operations as plating, painting and welding.

● A developmental area for Polyscope, according to CEO Patrick Muezers, is the development of new blends of PMMA with 20%+ Xiran SMA copolymer for higher heat PMMA automotive LED applications, including rear-light lenses and interior light guides. These blends can nicely meet requirements for such applications at lower cost, improving the flow of PMMA and achieving better optical performance, while also allowing for more design freedom.

Lightweighting.

● According to Jose Chirino, Americas technical director at LANXESS Corporation, Tepex continuous fiber composite laminates have gained significant ground into mass production components at OEMs. This innovative combination of continuous fibers with thermoplastics creates exceptionally high-strength and rigidity, coupled with extremely low weight of the finished parts. Current applications include the Honda Clarity rear bumper and door-module carriers.

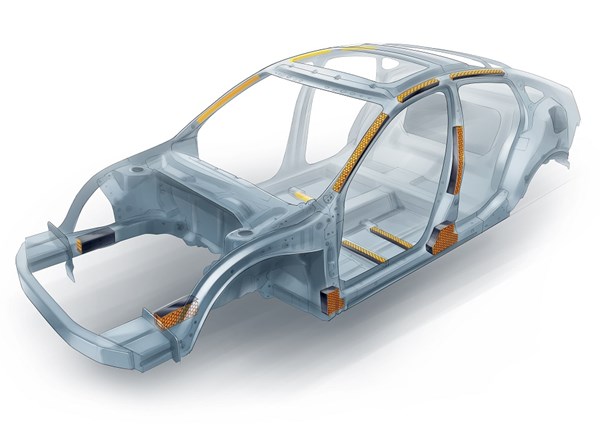

● Mixed material solutions are also on the increase, according to Scott Fallon, global leader of SABIC's automotive business. Looking ahead, the industry is expected to validate a greater number of applications based on hybrid solutions or the use of multiple materials, like thermoplastics and metal. One such application on a production vehicle is a floor rocker reinforcement on the Jeep Renegade, which replaces multiple steel stampings. This reinforcement part not only meets requirements for side-crash performance, but achieves 50% weight savings vs. an all-steel alternative.

Molded out of a blend of nylon and modified Noryl GTX PPE, the part is based on a thermoplastic honeycomb design with metal flanges. The part is also e-coat capable and allows for easy assembly. Other vehicle body-in-white (BIW) components like A/B/C pillars and floor cross-bars show potential for 5-8 kg (11-18 lb) of weight savings without compromising structural crashworthiness.

● PlastiComp, Inc., Winona, Minn., is targeting structural parts for its long-carbon-fiber (LCF) thermoplastic compounds and its unique hybrids of LGF and LCF in a unified pellet, says business-development manager Steve Ouendag. The unified pellets are currently available in nylon 66, PP, and TPU. The company is working with several Tier 1 suppliers on metal replacement in underhood and powertrain assemblies with LCF-PP and nylon. Weight savings as high as 50% can be achieved when replacing aluminum or cast metals.

● According to Jeffrey Helms, global automotive OEM corporate accounts director at Celanese Engineered Materials, as battery technology improvements plateau, electric vehicles manufacturers are looking to weight-reduction advancements to overcome range limitations and the associated consumer anxiety.

Selecting the right material and mold capability to enable ultra-thin-wall designs in electric vehicle components, including battery covers and trays, will enable them to meet these weight-reduction goals. Specifically, with Celstran high-flow long-fiber thermoplastic technology, material costs can be decreased by thin walling. In addition to enabling a 20-30% weight reduction, as well as a greater than 12% reduction in cycle time, the technology provides a substantial increase in glass fiber length in molded parts. This, in turn, provides higher strength and impact resistance.

● Henning Karbstein, manager new business development and idea management at the dispersions & resins division of BASF, addresses the company’s thermoplastic versions of its Acrodur acrylic binder systems. These one-part binders, supplied as aqueous solutions and latex dispersions, boast low viscosity for impregnating fibers, allowing production of prepregs at room temperature. These semi-finished goods exhibit thermoplastic behavior before cure. They are thermally formable and cure into thermoset composites at elevated temperatures with water as the only byproduct.

Karbstein notes that in automotive, the need for lighter and higher-performing materials is an ongoing race. Injection molded parts have been partially replaced by compression molded nonwoven composites. This processing change primarily displaced large flat sections of parts—such as interior door panels or shelves. Acrodur resin allows for composite fiber content of 75% and higher. In many cases, renewable natural fibers can be used with excellent physical properties. For complex part design features, such as ribs, lips or variable wall thickness, injection molding remains the process of choice compared with compression molding.

“A smart way of marrying the advantages of lightweighting with sustainable natural fiber composites and the design freedom of injection molding is the combination of these processes with overmolding. In this combined process, a nonwoven composite is inserted into an injection molding cavity in the large flat areas, In line with traditional injection molding, thermoplastics granules are subsequently injected to fill in the more complex features of the part design. This allows for lightweighting by thinning the part in the otherwise thick flat areas and displacing them with the natural fiber composite while simultaneously allowing for the traditional injection molding freedom of design.”

He adds that the combination of materials with compression and injection molding have been known to the industry for a long time with PP. However, compared to PP, Ultramid nylon enables improved mechanical performance, lightweighting and application temperatures. At the same time, the use of Acrodur as the binder for the fibrous composite insert does the same for the nonwoven insert.

● Electrification: There is an increased need for high-performance polymers like Amodel PPA and Ryton PPS for use in electronics for traction motors, inverters and 48-Volt technologies, according to Brian Baleno, global automotive business-development manager at Solvay Specialty Polymers. The type of components that are being developed with both these resins include connectors, resolvers, bus-bars, sensors and solenoids.

Amodell PPA product families AE-1XXX, AE-4XXX, and AE-8XXX are “electrically friendly.” They include grades with glass-fiber reinforcements ranging from 30% to 60%. Amodel PPA is replacing conventional nylon where new requirements demand higher voltage and retention of dielectric properties at elevated temperatures.

Ryton PPS is the material of choice when there is a combination of requirements that typically include temperature, dimensional stability, and flame retardance. This material is replacing both thermosets and metal in many of these electronic components. Depending on the operating environment, Solvay offers a range of PPS products that contain glass fiber or a combination of mineral filler and glass fiber.

PC Glazing/Windows

● SABIC’s Fallon says advancements in glazing, coating and manufacturing technologies have made PC-based windows a real possibility. A highly notable development is the launch of the rear-quarter window on the Buick GL. The largest of its type and featured on a production vehicle in China, the glazing is produced by Chinese Tier Shentong and represents the first manufacturing line for Lexan PC glazing production in China.

Interior—Instrument Panel Carriers

● Patrick Muezers, CEO of Polyscope, says the company has developmental hybrid materials, which will be sold under the Xiloy name and at a lower cost. The company has come up with an innovative way to compatibilize Xiran SMA with PP, and it is currently producing parts from this hybrid plastic in-house in a bid to optimize it. The company will target instrument panel carriers where SMA can meet a broader temperature range than PP—reaching from -35 C to 120 C (-31 F to 248 F). Muezers notes that the market has shifted heavily in this direction, and he points out that, versus more thermally stable amorphous materials, PP does not have as great low-temperature performance, particularly for air-bag deployment.

Related Content

Prices of Volume Resins Generally Flat or Lower

Exceptions in early March were PP and PS, which moved up solely due to feedstock constraints, along with slight upward movement in PVC and PET.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More