Absolute Robot Grips New Role as Custom Automation Integrator

NPE2024: ARI exhibit positions robot supplier as integrator of more complex custom downstream automation systems.

Share

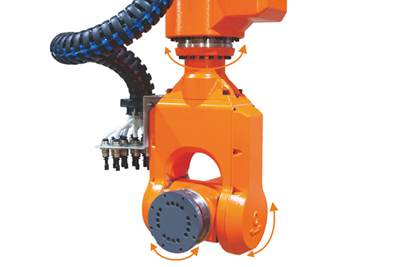

Absolute Robot Inc. is showcasing its capabilities as a custom automation integrator, not just a robot supplier. On display is a vertical insert molding cell with a Fanuc cobot (left), reflecting ARI’s recent certification as a Fanuc system integrator. Also, an updated Max-Series top-entry robot has new controls for up to 16 servo axes, up from five axes previously, enabling the robot to control multiple downstream functions. Source: Absolute Robot Inc., Fanuc

“This year at NPE, we are showing off the full bandwidth of our capabilities as a custom integrator.” That’s the mission statement for this week in Orlando, states Tim Lavigne, business unit manager for Automation at Absolute Robot Inc. (ARI).

“Up to now,” he explains, we supplied top-entry robots, end-of-arm tooling, guarding and conveyors – like others in the market. But customers said they were looking to go beyond press takeout into more intricate downstream operations.”

A key step in this direction for ARI was becoming an authorized system integrator for Fanuc six-axis robots in 2020. “What set us apart from other Fanuc integrators,” says Lavigne, is that we had a plastics background. We had injection molding expertise, and we knew the Euromap interface between robots and injection machines.

Tim Lavigne, ARI’s Automation business-unit manager, says, “I’m excited for this NPE. There was a lot of uncertainty. But perhaps after six years since the last show, ‘Absence makes the heart grow fonder.’”

Source: Absolute Robot Inc.

“We dove into our new role as a supplier of automation beyond top-entry robots. The pandemic slowed things down at first, but in 2023 our Fanuc side grew 600%, while the rest of the industry saw a downtick.” Here at the show, ARI is teaming a Fanuc CRX-10iA/L collaborative robot (cobot) in an automated cell with a Tayu 96-ton vertical injection press and two-station turntable, insert molding four spoons with overmolded handles. Tayu is a Chinese specialist in vertical machines and ARI partner since 2018. “We’ve seen a lot of attention on vertical presses lately,” notes Lavigne. “And 60% of our quotes for vertical machines in the past year have included automated cells.” He attributes that in part to the pressure of labor costs in the auto industry and medical devices and disposables.

Meanwhile, ARI is upgrading the automation capabilities of its flagship top-entry robots, the all-servo Max Series. A new controller launched last year provides up to 16 axes of control, up from only five on the previous controller. This allows control of multiple additional movements on the robot arm, as well as servos on downstream automation (such as an indexing rotary table). The mid-size MaxCW10-1600 robot in the booth (for presses of 470-800 tons) has six axes, including A+B+C wrist action, vs. only A+C or B+C offered previously.

Those axes are powered by new servomotors that provide 10-15% higher speeds. An updated “Y-free” function mirrors the ejector speed under power, saving 2-3 sec of cycle time versus cutting power to the Y-axis before ejection. Also new is a “safe torque off” (STO) function that puts the robot on hold – but still under power – when the safety enclosure gate is opened; and the robot picks up the cycle automatically when the restart button is pushed. This eliminates the use of an E-Stop button each time an operator enters the safety area, sparing the servos from a stressful power surge.

Related Content

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Absolute Robot Authorized as Fanuc Robot System Integrator

Absolute Robot is now an authorized Fanuc Robot System integrator, adding Fanuc’s 6-axis robot line to its current product offerings.

Read MoreSix-Axis Top-Entry Robot Debuts

NPE2024: Absolute Robot will debut the MaxCW10-1600A+B+C 6-axis top entry robot, featuring additional axes and updated control, as well as a Fanuc cobot automating a vertical press.

Read MoreCartesian Robot Line Enhances Control, Increases Speeds and Boosts Takeout Functions

Absolute Robot has upgraded its Max series of full-servo top-entry robots upgrading its control, speed and takeout functions with the Y-Free capability.

Read More