Six-Axis Top-Entry Robot Debuts

NPE2024: Absolute Robot will debut the MaxCW10-1600A+B+C 6-axis top entry robot, featuring additional axes and updated control, as well as a Fanuc cobot automating a vertical press.

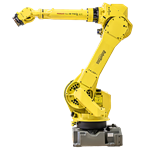

Absolute Robot will debut the MaxCW10-1600A+B+C top-entry 6-axis top-entry robot at NPE2024. Source: Absolute Robot

Absolute Robot Inc. (ARI) will present a variety of automation products at NPE2024, including the new MaxCW10-1600A+B+C top-entry robot. The latest Max-Series top-entry robot features an updated motion controller, which includes additional axes of motion and enhanced “Y-Free” on the demolding stroke. ARI says the axis options paired with faster motor speeds can reduce overall cycle time, with the updated “Y-Free” function enabling the robot to synchronize motor speed with molding machine ejectors to mirror part-eject speed.

The Max-Series control has up to 16 axes of control, up from only five axes on the previous control. In addition to enabling control of multiple additional movements on the robot arm, this also gives Max-Series users the ability to control servos on downstream automation, like an indexing rotary table. The additional robot axes transform an X, Y, Z cartesian robot into one that can spin, grab, flip and reorient parts. ARI notes that the layout, programming and form factor of the robot remain the same, keeping them economical and less complicated to operate than a floor-mounted, 6-axis robot arm.

The new generation robots are equipped with safe torque off (STO) ASDA A3 servo drives, updated from ASDA A2 drives. ARI says the new servo drives deliver a 10 to 15% increase in speed. The robot has 1,600-mm of vertical reach and a 2,500-mm traverse, with four vacuum and two gripper circuits shipped as standard, and 20 spare I/O ports in the control cabinet.

Cobot Pairs With Vertical Press

ARI’s booth also features a Tayo vertical injection molding machine with a rotary table and 4-cavity mold automated via a Fanuc CRX-10iA/L collaborative robot. ARI is an authorized Fanuc system integrator. The 96-ton Tayu press will mold spoons with an overmolded handle from a four-cavity tool, with the Fanuc cobot inserting the spoon into mold and extracting the completed spoon with an overmolded handle. The cell features a custom end-of-arm-tool and guarding from ARI.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.