Cooling Tower System Temperature Control Strategies

Temperature control strategies will have a significant impact on the ability of a cooling tower system to maintain the desired setpoint.

Two cooling towers roof mounted as part of a closed loop system.

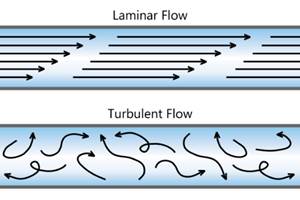

Cooling tower systems are an extremely effective method of process cooling. Changing the state of water from liquid to gas through evaporation absorbs significant amounts of energy, known as the latent heat of vaporization. This energy transfers from the water in the process stream that does not evaporate and results in a lower water temperature. Many factors determine how much energy a cooling tower can remove from a system. These include the water flow rate and entering temperature, the spray pattern inside the tower and the available surface area for evaporation, the airflow through the tower and the ambient conditions including temperature and humidity (expressed as wet-bulb temperature).

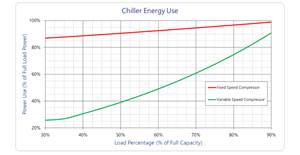

With so many factors influencing the amount of energy the tower can remove, the tower’s cooling capacity will fluctuate as these parameters change. Therefore, the outlet water temperature from the tower varies as well. The following is a review of a few concepts that improve the precision of the outlet water temperature control. These concepts provide multiple stages of temperature control/capacity control to help the tower system maintain setpoint. Additionally, these control methods help the system react to changing cooling demands more quickly.