Compressor Cycling

The most basic method of capacity control is compressor cycling. The chiller’s compressor drives the refrigeration cycle, which provides the system with cooling. A compressor is either on or off and runs at 100% speed whenever it is on.Cycling the compressor stops the cooling in the chiller. It is a straightforward concept, if you do not need the cooling, turn it off. However, there are a few issues with this design.

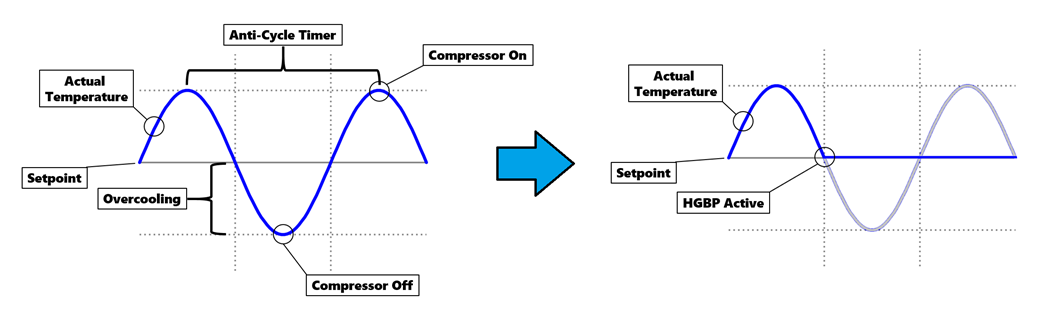

First, the on/off cycling can damage the compressor or reduce its life expectancy. For this reason, manufacturers require an anti-cycle delay that will only allow 12 starts per hour to protect the compressor. This means the compressor must wait at least 5 minutes from the time it last started before it can turn on again. As a result, the coolant’s temperature stability suffers. The oversized chiller will cool too much, triggering the compressor to cycle off.

While the compressor is off, there is no energy removal from the coolant and the energy builds, increasing the temperature. With the anti-cycle timer active, the coolant temperature can continue to increase, eventually overshooting the setpoint until the timer is finally satisfied. This scenario creates a wave-like pattern of overcooling followed by overheating. This repeats until the load on the system changes.

Hot Gas Bypass

The next method of capacity control addresses the lack of temperature stability from compressor cycling. It is hot gas bypass (HGBP) and refers to a modification of the refrigeration circuit in the chiller. It does exactly as the name suggests - bypasses hot gas directly to the evaporator. This creates an additional heat load that prevents the chiller from overcooling and needing to turn the compressor off. HGBP avoids the compressor cycling issue and the resulting temperature instability. However, this solution wastes significant energy. For example, a 10 ton chiller with only a 5 ton load still operates like a 10 ton chiller and consumes the same amount of energy a 10 ton chiller normally would.

Hot gas bypass (HGBP) bypasses hot gas directly to the evaporator to prevent the chiller from overcooling.

Larger capacity chillers can use a combination of cycling and HGBP because multiple compressors are used to meet the full design capacity. This design provides stages of turning compressors off or unloading. The more compressors, the more stages of unloading. With multiple stages, it improves the chiller’s ability to match the load with discrete steps. It avoids the large temperature swings and anti-cycle timers of a single compressor chiller. Additionally, with compressors off, it reduces overall energy consumption. On the last stage or compressor, HGBP ensures temperature stability while only wasting a fraction of the energy.

The above diagram demonstrates how HGBP is configured within the refrigeration cycle.

Digital Scroll Compressor

For chillers that are limited to one or two compressors, new technologies can actively adjust capacity while also saving energy. A digital scroll compressor operates in two states – the loaded state and unloaded state. In the loaded state, the compressor operates like a standard scroll at full capacity. In the unloaded state, there is no compression or capacity. Controlling between these two states, loaded/unloaded, the compressor earns its “digital” name. By physically separating the scrolls in the compressor, it will move from loaded to unloaded and back. The amount of time spent in each of these two states modulates the capacity of the chiller. With no compression, the compressor consumes much less energy while remaining on. This avoids the cycling issues mentioned earlier.

Variable Speed Design

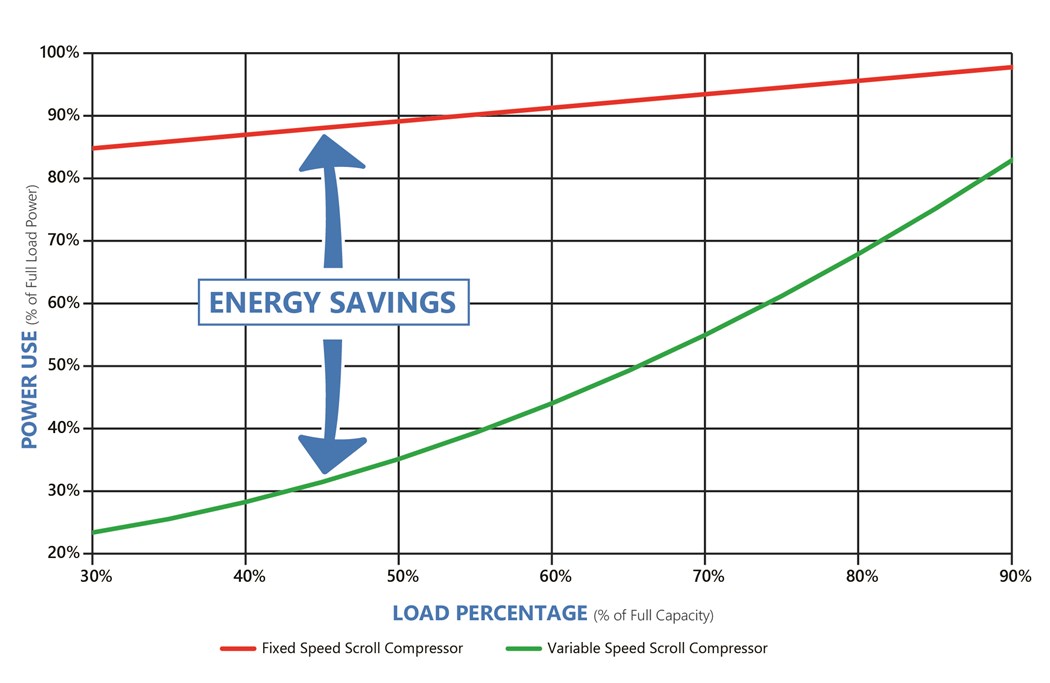

The leading technology for capacity control is a true variable speed design. The chiller’s controller constantly monitors the heat load. Using a variable speed drive, the system adjusts the compressor speed for peak efficiency and temperature control, eliminating the need for a hot gas bypass. By automatically adjusting the speed, the chiller only works as hard as necessary to provide the optimum performance with significantly reduced energy consumption. Studies have shown that a 20% reduction in compressor speed can lead to 51% energy savings. This solution encompasses the best performance and protections for the system available today.

An example of savings using a variable speed compressor.

Based on your process’s cooling demand, and the overall variability of that demand, the right capacity control solution is available to match your needs.