Avient Launches Upgraded CAE Capabilities for Materials Selection

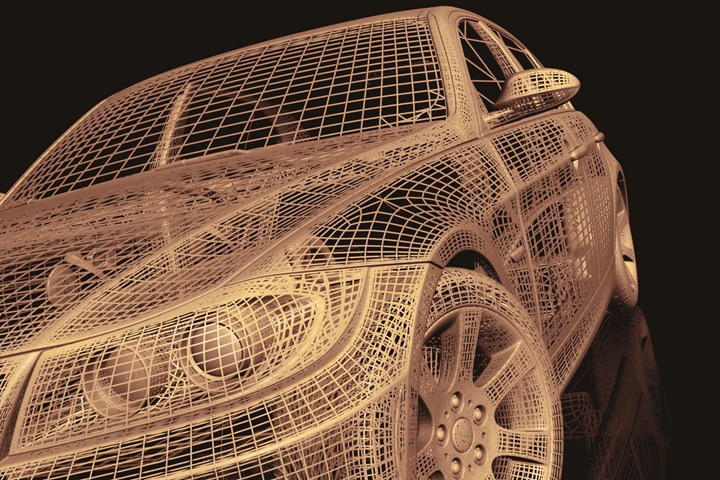

Enhanced visual simulation designed to support the use of plastics in structural applications.

Avient has launched its newly upgraded, advanced computer-aided engineering (CAE) capabilities designed to help customers more precisely predict the behavior of fiber-reinforced polymer materials in structural metal replacement applications to reduce design iterations and accelerate the speed to market. This predictive simulation technology factors in conventional (isotropic) and advanced (anisotropic) modeling data from material characterizations, mold filling analysis, and finite element analysis (FEA). Based on static and dynamic data, the virtual simulations can more accurately predict where an injection molded plastic part may crack or break when exposed to physical loading forces or a sudden impact (crash simulation). The complex modeling software can also factor in temperature and humidity levels. These enhanced capabilities can help further optimize part design and material selections, mitigate risk, improve performance, and reduce costs early in development.

Especially useful for structural applications, the new global capabilities complement an existing suite of comprehensive design and technical services to improve Avient’s ability to simulate the expected performance of short, long, and continuous fiber composites. Furthermore, the advanced modeling can help manufacturers and molders to better identify and address potential deficiencies, assess performance before investing in tooling or physical testing, and understand component performance / whole system operations. In addition, designers may access material data and models for a growing number of Avient’s fiber-reinforced solutions using Hexagon’s Digimat MX (Material Exchange) software platform. Currently, 168 long fiber models are available for Avient materials, representing nearly half of the long fiber models in Digimat.

Said Amit Kulkarni, global director of technology for Avient’s Specialty Engineered Materials unit, “From the beginning to the end of the design process, we aim to help our customers streamline application development, improve speed to market, and have increased confidence in the performance of reinforced polymer materials in structural applications. This enables customers to replace metal with plastic and take advantage of benefits like sustainability through lightweighting, design freedom, and easier processing.”

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.