Ensinger Acquires Ineos Styrolution’s StyLight Thermoplastic Composite Business

The acquisition adds an exclusive SAN-based product range to Ensinger’s comprehensive thermoplastic composite portfolio.

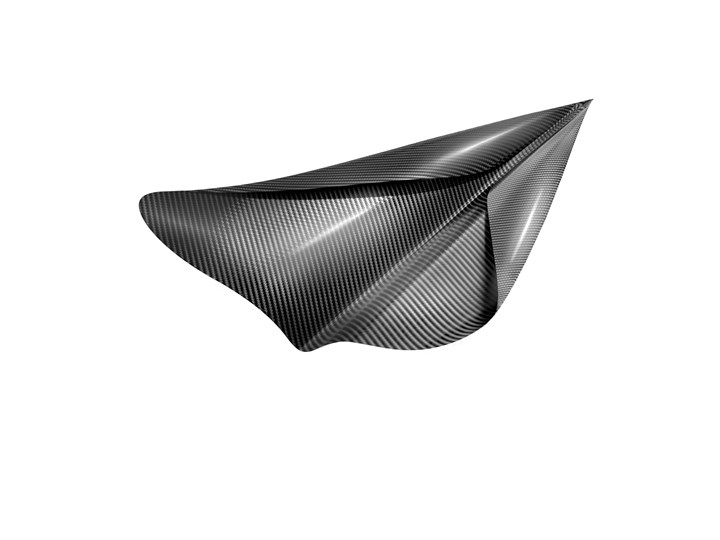

Germany’s Ensinger Group (U.S. office in Anaheim, Calif.) has acquire the StyLight thermoplastic composite business from Ineos Styrolution; an acquisition that adds an exclusive SAN-based product range to Ensinger’s comprehensive thermoplastic composite portfolio. SAN based products bring many new thermoplastic composite possibilities to the market such as carbon, glass and natural (flax) based fiber products for aesthetic materials, semi structural, and over molding applications to name a few.

Ineos Styrolution developed and successfully launched the innovative StyLight product line at the K Show in 2016. Since then, the new solution has triggered a lot of interest and business with many customers across a range of industries. “The business continues in Ensinger’s experienced hands, serving the existing customer base and seeking future growth potential to enhance the Company’s current position in the international thermoplastic composites market”, sais Daniel Grauer, international business development manager, Ensinger Composites, who will be the primary contact for all sales and customer enquiries. Ensinger has rebranded StyLight to its thermoplastic composite materials brand Tecatec, to align seamlessly with its current product offerings to the international market.

The addition of the StyLight business is the next strategic building block in Ensinger’s journey to becoming one of the only manufacturers able to offer the complete value chain of thermoplastic composite products, according to Ralph Pernizsak, managing director, Ensinger Group. “We are pleased to come to this agreement. We are convinced that these innovative composites have a bright future ahead and we are certain that Ensinger is the ideal new home for this product line.”

The Ensinger Group is engaged in the development, manufacture and sale of compounds, semi-finished materials, composites, technical parts and profiles made of engineering and high-performance plastics. To process the thermoplastic polymers,

Ensinger uses a wide range of production techniques, such as extrusion, machining, injection molding, casting, sintering and press molding. With a total of 2,600 employees at 33 locations, the family-owned enterprise is represented worldwide in all major regions with manufacturing facilities

Related Content

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.