Components Help Route Cooling Lines

Diverting rods and O-rings provide designers with more options to route cooling lines within their tools.

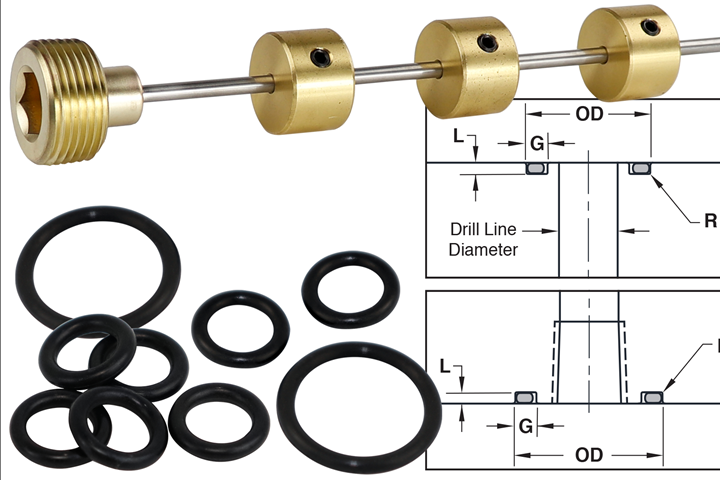

Progressive Components has introduced new diverting rods for route cooling and O-rings for sealing cores. The company says the O-rings give mold designers an industry-standard that includes the machine groove detail. Standardizing these makes replacement during mold maintenance easier. Progressive says the O-rings are available for both face- and core-sealing applications and are offered in two material options: Buna-N for temperatures up to 225 F and Viton for temperatures up to 400 F. Sizes range from .566 to 4.872 in. OD, with cross-sections of 1/16th, 3/32nd, and 1/8th.

Progressive notes that since different shops have different practices for designing the groove detail for O-rings within their molds, and that by providing CAD geometry in seven formats it can help establish a standard. Also, by making O-rings available from a mold component supplier and having them listed in the bill of materials, molders won’t need to search industrial suppliers for replacements downstream.

The company’s new diverting rods and plugs route water flow within cooling circuits. While the mold is on the bench, plugs can be assembled along the locating rod, enabling positive installation and easy removal. The rod is designed to stay in the center of the cooling channel, allowing maximum heat transfer

Diverting rods and O-rings provide designers with more options to route cooling lines within their tools.

Related Content

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.