Fakuma 2023: More Details on New Machine Line

Wittmann Battenfeld has released more details on the new EcoPower B8X debuting at Fakuma (October 17-21; Friedrichshafen, Germany), which it previously announced.

Share

Read Next

At Fakuma (1204 in hall B1), Wittmann Battenfeld will introduce the EcoPower B8X injection molding machine, which it says provides even greater energy efficiency that its predecessor, with those gains coming primarily from upgrades to the injection unit and toggle.

A greater selection of injection unit sizes has been introduced, enabling customers to adjust their machine more accurately to their specific process needs. Some of the injection units are available in a Plus version, with twice the injection speed, and the injection unit’s spindle is now lubricated with oil versus grease, which reduces frictional resistance, with the overall number of different lubricants required also reduced.

Wittmann Battenfeld’s EcoPower B8X features a pivotable injection unit, easing access to the screw and barrel.

Photo Credit: Wittmann Battenfeld

Wittmann Battenfeld notes that EcoPower’s injection unit has been harmonized with the SmartPower’s injection unit, and it can now swing outward, creating easier access for screw and barrel changes. Regarding maintenance, the injection unit has also been equipped with a sum connector for the heating system, including screw coding, which ensures faster error-free barrel changes. In addition, the sum connector automatically calculates the screw diameter.

The sum connector on the EcoPower B8X can automatically calculate screw diameter when connected.

Photo Credit: Wittmann Battenfeld

The control cabinet houses all electric components of the barrel-heating system, easing access, with a separate plug-in addition to the sum connector installed for the nozzle heater, facilitating fast replacements of the nozzle heater band.

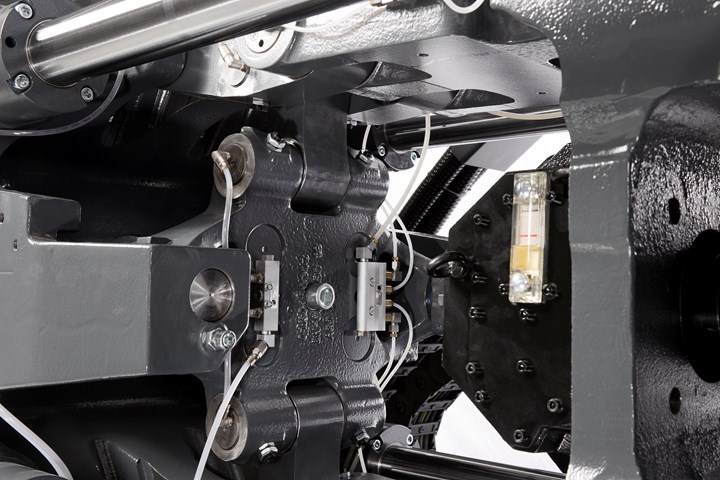

On the clamp side of the machine, the EcoPower B8X’s toggle lever has been kinematically optimized, reducing the force required for buildup by 15%. This has lowered overall stress on the servomotors and led to a further reduction of energy consumption. This also enables more dynamic movement and faster dry cycle times. To extend the toggle lever’s service life, the crosshead guides have been reinforced, and new hard bronze connectors with a special alloy have been installed, as well as larger toggle bolts for better force distribution among the bearing positions.

The toggle lever crosshead guides of the EcoPower B8X have been reinforced.

Photo Credit: Wittmann Battenfeld

The machine’s B8X control features system components developed in-house, including the X4 booster for the drive units. Wittmann says this has been directly adapted to the servomotors, permitting a higher internal clock frequency sampling rate, for shorter response times to sensor signals and higher repeatability.

The new EcoPower B8X will be available for the European market following Fakuma in clamping forces from 550 to 1,800 kN (60 to 200 tons), and with injection volumes ranging from 10.8 to 778 cm3 (.36 to 26 ounces). The sizes up to 5,500 kN (620 tons) with volumes up to 3,012 cm3 (102 ounces) are still on offer in the current version.

A Wittmann spokesperson told Plastics Technology the EcoPower B8X will be available in the U.S. market starting at NPE2024 (May 6-10; Orlando), in a size range from 60 to 330 tons.

Related Content

-

Next-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

-

Absolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

-

Injection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.