Halogen-Free & Red-Phosphorus-Free FR Nylon 66 for E&E, Automotive

Asahi Kasei’s Leona SN boasts excellent retention of properties, good surface appearance and laser transparency and printability.

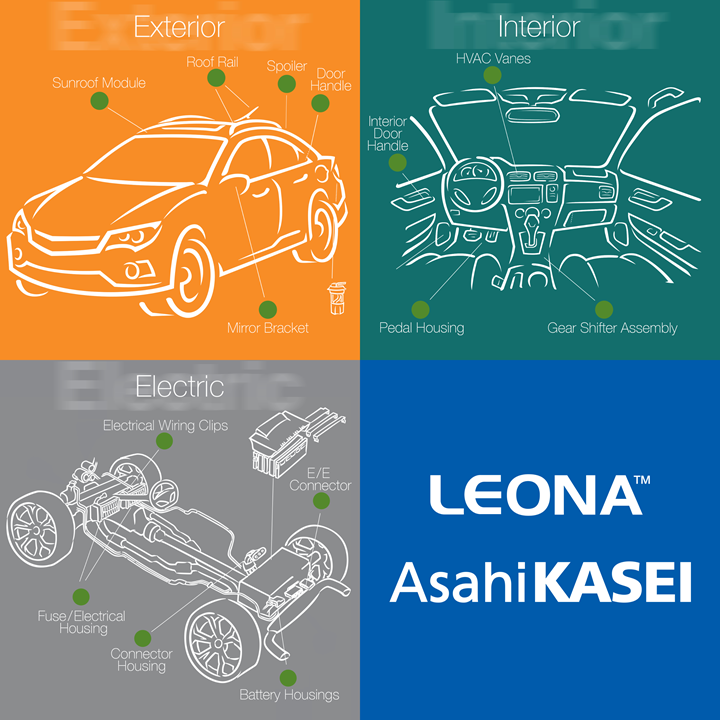

A series of halogen-free and red-phosphorus-free flame-retardant (FR) nylon 66 resins now available from Asahi Kasei, are targeted to E&E applications such as breakers, magnet switches, and compressed-air valves as well as automotive applications in powertrain parts and EV charging stations.

The new Leona SN series resins boast UL 94 V-0 and relative tracking index (CTI) of 600 V, good surface appearance, good laser transparency (Na) and laser printability (BK). Also claimed are enhanced productivity thanks to clearer and faster laser marking on gloss surfaces, and less mold deposit than conventional halogen-free and red-phosphorus-free materials. Moreover, these resins have been shown to have a higher retention rate of physical properties in a conditioned state. Although the properties of similar halogen-free nylon 66 materials are significantly reduced, Leona SN can still maintain a high level of tensile strength and flexural modulus after moisture absorption. The material can also meet the highest HL3 hazard level requirements for R22 internal components and R23 external components in the European railway fire safety standard EN 45545.

The Leona SN series is part of Asahi Kasei's Leona nylon resin series. This series of products also includes anti-ultraviolet grades (SU series) and semi-aromatic grades (SG series), which can be used to replace metals and automotive interior applications. These materials are all said to have characteristics that combine surface quality, processability and excellent mechanical properties.

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

Soft Prices for Volume Resins

While PP and PE prices may be bottoming out, a downward trajectory was likely for all other volume resins, including engineering types.