High-Performance Medical PC for Overmolding with LSR

Covestro’s new Apec 2045 copolycarbonate boasts higher heat resistance to enable lower production time and cost.

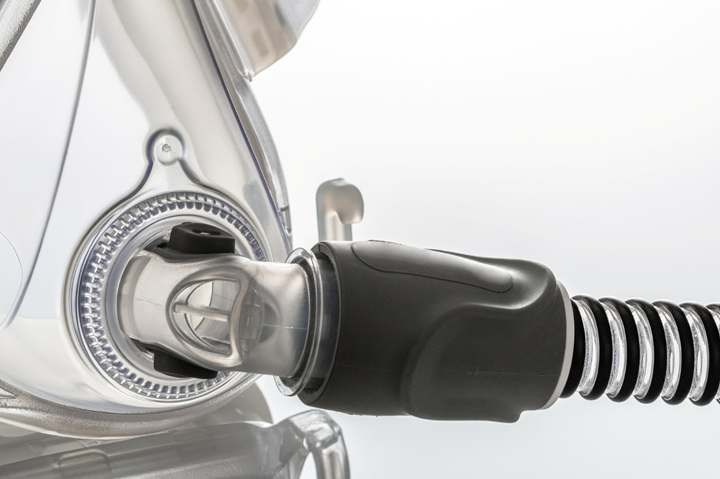

A new medical copolycarbonate, Apec 2045, from Covestro with what is said to be the highest heat resistance is designed to enable molders and medical OEMs to significantly lower production time and cost, without sacrificing quality, performance or appearance. Overmolding with LSR is commonly used to produce respiratory masks and other medical devices requiring molded-in seals. Highlighted at the 2024 MD&M West (February 6-8 in Anaheim, California), Apec 2045 offers many other key benefits including: durability, transparency, and biocompatibility testing according to ISO 10993-1 and USP Class VI for contact of 30 days or less. It also supports sterilization methods such as irradiation, autoclave and hot air, and reportedly offers consistent and efficient processing.

Furthermore, the material may contribute to customer sustainability goals, as it can enable circular business models by supporting close- and open-loop recycling, as well as the possibility of attributed bio-circular content. Says Covestro’s global healthcare technology lead Pierre Moulinie, “We work closely with our healthcare customers, and recognized that we could offer a polycarbonate made for highest curing temperatures in silicone overmolding, helping them more than double production volumes in the same amount of time due to shorter cycle times. Our experts provide support every step of the way when switching to this new high-heat Apec copolycarbonate grade—for example, simulating material performance in specific applications and calculating cost benefits with our LSR calculator tool.”

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.