Mold Documentation Tracking System Updated

MoldTrax’s MTWEB now allows visibility in multiple locations and five languages.

MoldTrax has introduced MTWEB—the newest version of its mold documentation tracking system. Created specifically for efficient tracking of the performance, maintenance efficiency and repair costs of tools and dies, MoldTrax allows users to standardize terms throughout the system.

The latest update includes visibility in multiple locations and five languages in the corporate version. The program now automatically converts raw data into clear graphics so users can quickly spot high-cost or high-frequency issues, including across user-specified date ranges. In addition, a “cycle count” field has been added which can be populated manually or electronically for live updates from a user’s ERP, with a preventative maintenance (PM) Alert report that shows approaching PM cycle points by priority: green, yellow or red. The expanded hot runner section includes more fields for maintaining manifolds and related components, and the Mold Performance report shows maintenance and repair costs, including tooling and labor, by cycles, defects and run hours.

The Tooling Inventory section added a link field to instantly connect to the component supplier page for easy ordering, while the Check-Sheet lets users list components of a mold or part that require periodic inspection. The Tool Risk and Condition Indicator (TRACI) calculation has been added and is based on the mold’s age, total cycles, steel type, resin type and molder’s location.

MoldTrax will be exhibiting at Amerimold 2021 (Sept. 21-23; Donald E. Stephens Convention Center; Rosemont, Ill.)

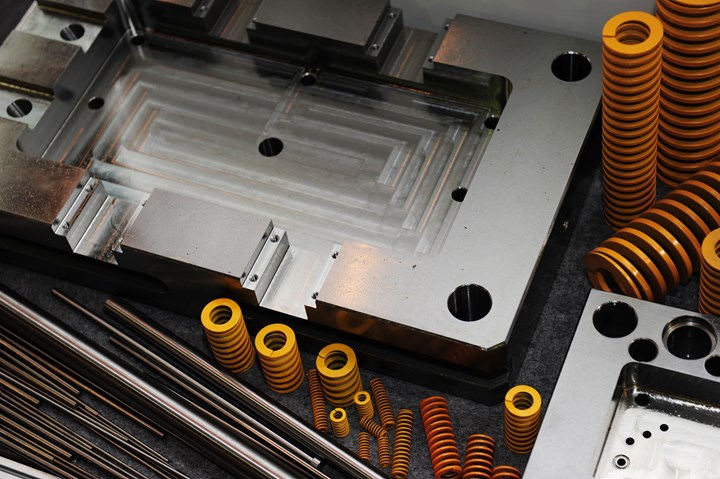

MoldTrax MTWEB documentation tracking system helps molders keep track of a tool’s production and service history.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.