Nylon/Modified PPE Resin for Demanding Automotive Applications in Hot and Humid Conditions

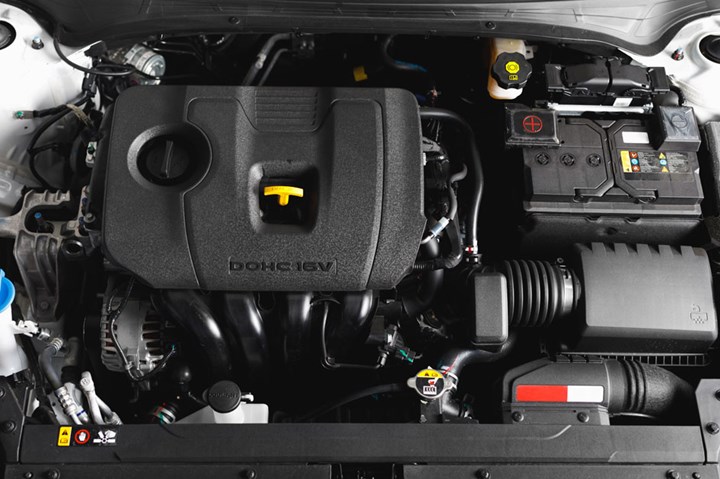

SABIC’s new Noryl GTX 9500 resin boasts superior dimensional stability, retaining improved balance of mechanical properties when exposed to heat and humidity in underhood and other applications.

The newest addition to the range of unfilled Noryl GTX family of nylon and modified PPE resins from SABIC is said to deliver superior dimensional stability under hot and humid conditions in highly demanding automotive applications. Noryl GTX 9500 has been shown to retain a better balance of mechanical properties when exposed to heat and humidity typical of automotive underhood environments, than nylons 6 and 66 resins, along with comparable high-flow and high-temperature performance.

Its dimensional stability and mechanical property retention under a wider range of temperatures and humidity – together with high flow performance – can open opportunities for thin-wall designs that reduce weight. Target applications include vehicle junction boxes, connectors and other applications requiring dimensional stability. This material also demonstrates a potential for use as the base resin in carbon fiber-reinforced thermoplastic composites used in structural and body components, and for applications in the industrial, aerospace and marine markets.

The strong tendency of nylon resins to absorb moisture and water, which is exacerbated by elevated temperatures, may cause softening, loss of stiffness and warpage. Noryl GTX 9500 resin offers significantly lower water and moisture uptake than nylon, even under high heat conditions, up to 150 C/302 F. In fact, SABIC testing demonstrated that this resin absorbed 21% less moisture at equilibrium than nylon 66, and 58% less than nylon 6. With moisture absorption at equilibrium, GTX 9500 surpassed nylon in dimensional stability. GTX 9500 resin had a total dimensional change (flow direction and crossflow direction) at equilibrium of 0.29%, while nylon 66 has a total change of 84% and nylon 6 had a total change of 165% higher than this Noryl resin. This improved dimensional stability offers benefits for moisture-sensitive applications, including reducing warpage to minimize scrap rates and enabling designs with thinner walls to support light-weighting. The resin also demonstrates exceptional retention of mechanical properties – flexural modulus, tensile modulus and flexural strength – under wet conditions compared to nylons 6 and 66. This material also surpasses incumbent Noryl GTX grades in terms of water and moisture uptake, dimensional stability and property retention.

Related Content

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.