Process Cooling: Variable-Speed Packaged Chillers Save Energy

Delta T Systems ups the size range of its VS Chillers to 60 tons.

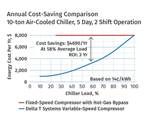

Expanding the range of its VS Chillers, Delta T Systems is now offering these units—previously available from 1 to 30 tons—in sizes of 40, 50 and 60 tons. They come standard with four variable-speed compressors that are said to operate effectively at 10% to 100% of rated capacity. According to the company, VS units provide up to 50% energy savings over chillers regulated by conventional hot-gas bypass systems (see May ’17 Close-Up for more details). The units are said to pay for themselves in less than 3 yr.

Available in air- or water-cooled versions, the units have variable-frequency drives (VFD) for soft starts and reduced compressor cycling. Other features include variable-speed condenser fans; oversized, stainless-steel, brazed-plate evaporators; one large central pump tank; individual redundant refrigeration circuits; and industry 4.0 controls design.

Related Content

-

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

-

Follow These Best Practices When Working With Heat Transfer Fluids

Effectively choosing, operating and maintaining thermal fluid can positively impact productivity in plastics processing.

-

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.