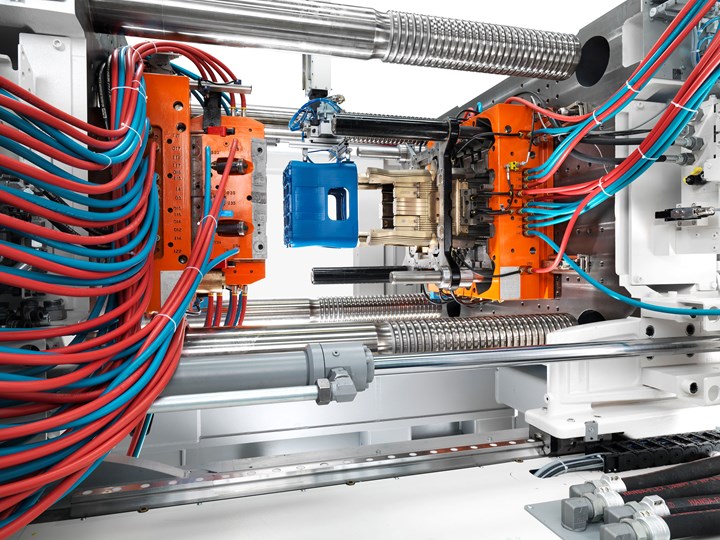

Robot Synchronizes Movement with Machine for Faster Takeout

The new “synchronous motion” function from KraussMaffei Automation reportedly shortens demolding time by up to 35% while allowing up to 6% faster cycles.

KraussMaffei Automation, the robotics division of the Münich-based supplier of plastics processing machinery, has introduced “synchronous motion”, allowing robots to synchronize with the ejector function of a molding machine and enter a mold while the platens are still in motion. KraussMaffei notes that in addition to speeding up the molding process, this also reduces the need for pneumatic systems.

KraussMaffei says that normally, a robot does not receive the enable signal until the mold is completely open. Using the “synchronous motion” function allows for earlier entry of the robot so that it arrives at the removal position during the opening movements of the machine.

Beyond keeping nonproductive time as short as possible, KraussMaffei notes that this technology can also make it possible to eliminate complicated gripper hardware. Ejector movement can be used for difficult-to-demold parts with the robot gripping the finished part during the demolding process as the ejector pushes the component onto the gripper. This requires a pneumatic system for the gripper during this “depressurize” step. If, however, the gripper moves along with the ejector, no pneumatic system is required. Depending on the complexity of the application, the synchronization can align with the clamp, part or ejector movement, allowing molders to define the degree of optimization.

KraussMaffei reports that synchronous motion enables demolding time to be reduced by approximately 35%. In the production of trash containers, for example, KraussMaffei says this reduction in demolding time equates to a 6% reduction in the total cycle time. In terms of impact on profitability, the company says the resulting boost in production can increase turnover up to 5% for pallets and up to 4% for crates.

KraussMaffei offers synchronous motion both for new machines and as retrofits for the MC6 controls on existing machines. It works with KraussMaffei’s LRX series linear robots and its IR industrial robots.

With the synchronous motion function from KraussMaffei, the gripper of the robot starts faster, saving valuable cycle time

Photo Credit: KraussMaffei

Related Content

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

New Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.