Kiefel Division, Brueckner Group USA

50 Education Way

Dover, NH 03820 US

603-929-3900

Info@brueckner-Usa.com

kiefel.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Kiefel Division, Brueckner Group USA Supplies the Following Products

- Bag-making Machinery

- Heat Sealing/Welding

- Mold Making and Repair Equipment

- Mold/Tooling Design Services

- Thermoformers

- Thermoforming Molds

- Ultrasonic Welding

Editorial, News, and Products

-

Refurbishing Service for Biax Lines

NPE2024: Clip and chain systems for film-stretching lines can now be overhauled in the U.S.

-

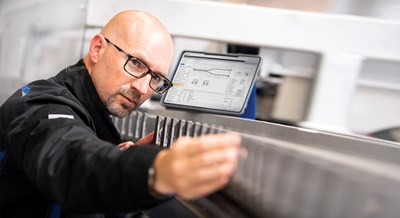

Upgraded Former is Faster, More Precise

New features reportedly offer more efficient production of trays, containers, hinged boxes, pallets, blisters, lids and technical products.

-

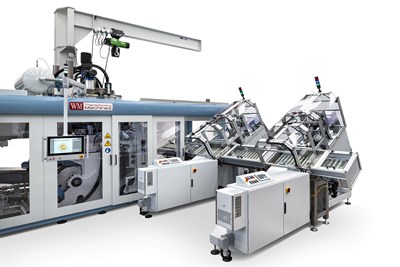

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

-

Brueckner Group USA Moving to Bigger Space

New facility in New Hampshire will serve the local customer base better and enhance capabilities in the North American market.

-

Thermoforming Machinery Specialist Kiefel Expands its Natural Fiber Expertise

With its new technology center, Kiefel is investing in its own sustainable packaging research activities with a focus on natural fibers.

-

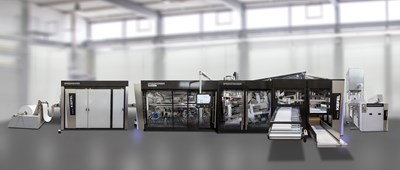

Thermoforming: Next-Generation Cup Former

Front-to-back enhancements come with no increase in machine footprint.

-

Thermoforming: Steel-Rule Former is Fast, Easy to Operate

Next-generation Speedformer also billed as energy efficient.

-

Decorating/Finishing: New Automotive Decorative Laminating Technology Cuts Costs, Boosts Quality

Describing it as a “revolution in vacuum lamination,” Kiefel GmbH in Germany has launched Tailored Blank Lamination (TBL) technology for automotive interior components such as door and instrument panels, consoles, storage compartments, pillars, etc.

-

Thermoforming: Enhanced Cup Former

High-speed former now offers enhancements in cooling, speed and controls.

-

Thermoforming: Buffering, Unloading Station

Unit can be added on to machines from various suppliers.

-

NPE Wrap-Up: News in Primary Machinery, Part 1

Rounding up details from the Big Show not previously reported in all our other coverage, here’s more news in injection and blow molding, extrusion and compounding. Next month, we’ll conclude with recycling/scrap reclaim, robots, tooling, auxiliary equipment, materials and additives.

-

Novel Thermoform Tooling Helps PP Coffee Pods Float

Tool forms pods with extremely low material densities, allowing them to float and be recovered in water-separation recycling systems.

-

Trend Watch: What to Look for in Thermoforming

At NPE2018, look for IML technologies and advancements to increase speed and productivity among thermoforming exhibitors.

-

K 2016: Connectivity & Collaboration in Robotics & Automation

Besides a handful of new robots and pickers, the big themes were modular ‘plug-and-play’ automation, Industry 4.0 connectivity, easier programming, and safer collaboration with human workers.

-

Blow Molding: New Machines Take on Challenging Shapes

From very small to very large, from hotel amenity bottles to automotive jounce bumpers, new and upgraded machines tackle difficult jobs while improving productivity, quality, and energy efficiency.

-

K 2016 Preview: Thermoforming

Machine builders put the pedal to the metal with new packaging lines that set speed records. You’ll also see a new ‘twist’ in thermoforming.

-

K 2016 Preview: Blow Molding

Looking for speed and energy efficiency? Take your pick of new all-electric, hybrid, and servo-hydraulic machines.

-

R&D Thermoformer: Tek Pak Is Launch Pad For New Products

Toolmaker and thermoformer takes concepts to production-ready parts in record time.

-

THERMOFORMING AT NPE: Machines Get Faster, More Flexible & Precise

They’re more energy-efficient, as well.

-

Thermoforming News at K 2013

New machinery and tooling developments for thermoformers debut at K.

-

K 2013 Preview: Thermoforming

Speed, versatility, control, and cost savings are keys to new thermoforming machines for packaging and industrial applications

-

Thermoforming at NPE: Machines Raise Performance Bar

Exhibitors at this year’s show introduced an assortment of new machines and upgraded models with designs incorporating the latest in mechanical, hydraulic, and electronic technologies.

-

Auxiliaries at NPE: New Solutions from Material Preparation To Post-Mold Operations

There will be an extraordinary range of new auxiliary equipment on display at the show.

-

Thermoforming at NPE: Less Scrap, More Power For the Buck

Most of the developments will focus on in-line systems.

-

THERMOFORMING: New Roll-Fed Systems Boost Output & Flexibility

Continuous in-line packaging systems headed up the K 2010 thermoforming news as suppliers launched a range of roll-fed systems with greater capacity, more flexibility, and improved automation.

-

K 2010 Preview, Thermoforming Productivity Enhancements Reign

At K 2010, thermoformers will be greeted by numerous advances in inline machines for packaging.

-

Progressive Injection Molder Pioneers in Thermoforming IML

When you’re a successful injection molder with more than 40 years under your belt and more than 50 presses producing 1.8 billion containers and lids for food-packaging containers annually, what do you do when you feel the time is right to expand?

-

Thermoforming at NPE 2003

There will be fewer thermoforming machines on display at NPE 2003 than at many recent NPEs.

-

NPE 2009 Wrap-Up: New Machinery for Thermoforming

NPE had its share of innovations in thermoforming, notably a new machine that opens the small-bottle market to thermoformers. New trim stations offer more in the way of output and versatility. And more machines are now outfitted with off-the-shelf controls to facilitate servicing. A line of formers from Australia also arrived in the U.S. (Note: additional NPE thermoforming news appeared in May and June—see Learn More box.)

-

NPE News in Thermoforming

For thermoforming of both heavy-gauge sheet and thin-gauge packaging, the show will present new machines with unusual flexibility, able to form a wide variety of products and materials.

-

Thermoforming: Ready for In-Mold Labeling?

After several fits and starts over the last decade, thermoforming IML appears ready for prime time, thanks to improvements in output and labeling technology. For now, the action is mostly in European packaging.

-

NPE 2006 News Wrap-Up: Thermoforming

Several new processing technologies unveiled at NPE point to thermoforming’s growing capability to produce in-mold labeled and decorated plastic parts.

-

What to See at NPE 2006: Thermoforming

Like many other NPE exhibitors, thermoforming equipment suppliers are taking less machinery to this year’s Chicago event.

-

K 2004 Wrap-Up on Thermoforming: Twin Sheets and High-Speed Packaging Share Center Stage

Innovations in thermoforming at K 2004 included new twin-sheet technology for automotive fuel tanks, a highly flexible and modular "plug-and-play" industrial vacuum former, and a range of high-speed units for cups and packaging.

-

NPE News Wrap-Up: Extrusion

Gearless extrusion, cryogenic profile calibration, wireless data communications, and automatic start-up of blown film lines are just a few of the new ways to raise efficiency and output that were highlighted at NPE.

-

Servos Drive Faster Packaging Systems

High-speed packaging systems dominated thermoforming news in Dusseldorf. A new shallow-draw, servo-driven system promises to make formed PP deli lids competitive with injection molded LLDPE. Other new machines use electric servo motors to speed forming of PS, PE, and PET packaging.

-

Thermoforming (K 2001 Preview)

Thermoforming equipment displays at K 2001 focus on innovations in trim-in-place packaging, especially for PP food containers. There is also action in improving productivity of heavy-gauge industrial forming machinery.