Additive Manufacturing

American Manufacturing Steps Up to the Coronavirus Challenge

Plastics processors are among the manufacturers that stepped up big-time in the face of the global COVID-19 pandemic. I’m proud to turn over this space this month to Rick Kline Jr., president of our parent company Gardner Business Media, whose comments below (edited) appeared originally March 31 in a OpEd piece published by the Wall Street Journal.

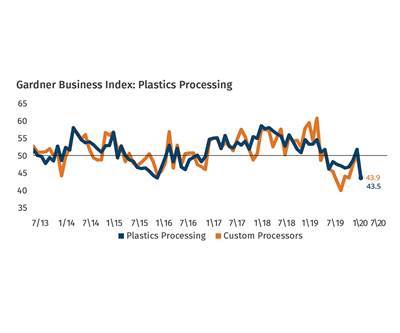

Read MoreProcessing Index Contracts as Coronavirus Disrupts Economy

COVID-19 results in weaker new orders, production dips and a disrupted supply chain in March. But for how long?

Read MoreHP Provides Updates Regarding its Efforts Around COVID-19

To date, HP and its global community of partners and customers has produced more than 150,000 parts for medical applications and growing.

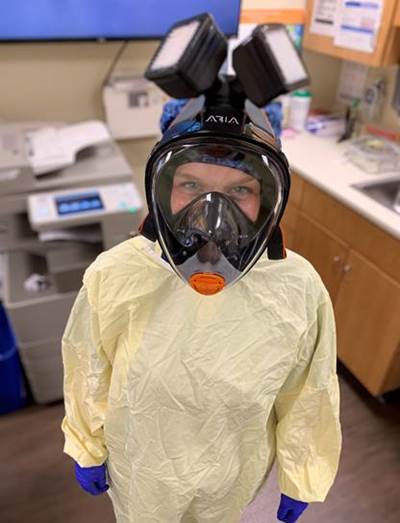

Read MoreMack Helps Convert Snorkeling Mask into Much-Needed PPE

A former employee connection, the need for a tight turnaround and a desire to use existing filtration—how Mack Molding’s Synectic redesigned a snorkeling mask into Personal Protective Equipment (PPE).

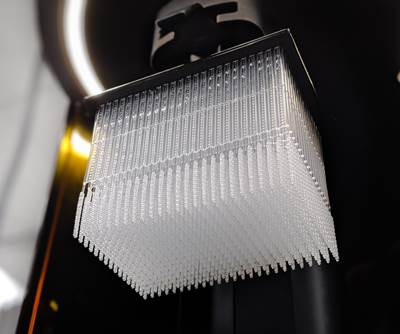

Read MoreStratasys and Origin Partner to Bring 3D-Printed Nasopharyngeal Swabs to Healthcare Providers

Origin plans to increase production from 100,000 per week to over a million per week by May.

Read MoreBoeing Delivers 3D Printed Face Shields to Healthcare Professionals

Solvay provided the clear film for the face shields whereas Trelleborg Sealing Solutions donated the elastic used for the adjustable headband.

Read MorePlastics Industry Enlists to Fight Coronavirus

All types of processors and machinery and materials suppliers and service providers are refocusing resources to combat COVID-19.

Read MoreCarbon 3D Prints Test Swabs and Face Shields in Response to the Coronavirus

Resolution Medical is among the first manufacturers to use the Carbon Platform to 3D print a conformal lattice swab, creating a medical device for the testing of COVID-19.

WatchMaterialise Develops 3D Printed Oxygen Mask to Address Shortage of Ventilators

The Materialise NIP Connectors will be manufactured at the company’s certified printing facilities in Belgium and Plymouth, Michigan and on-site 3D printing facilities of qualified partners. Materialise is looking for partners to get this solution to as many patients as possible.

Read More3D Printing Helps Close the Loop for Armor’s Circular Economy

Manufacturing 3D printing filament was first a way for Armor to recycle its own reclaimed plastic waste. But now, this business unit is helping to close the loop on sustainability for plastic 3D printed products.

Read More