best practices

Hitting the Numbers, Part 1: Communication is Key

Start with an up-front review, discussion and collaboration with the customer.

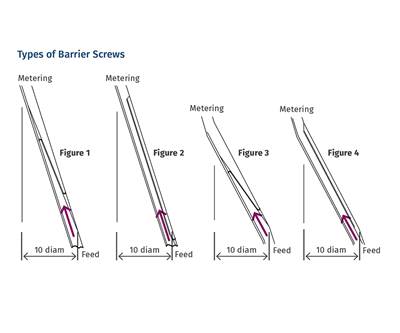

Read MoreWhich Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreService & Response Drive Growth of Custom Compounder

Lanier Color has experienced an eightfold increase in business since 2000. Its focus on technical support and customer service help explain why.

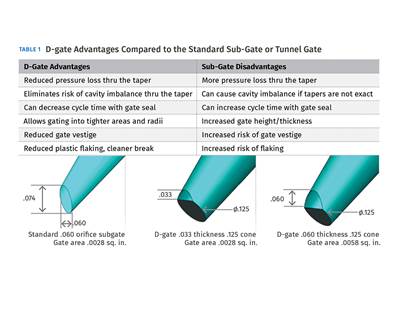

Read MoreGating Revisited

An overlooked factor in injection molding has outsize influence on the process and part quality.

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

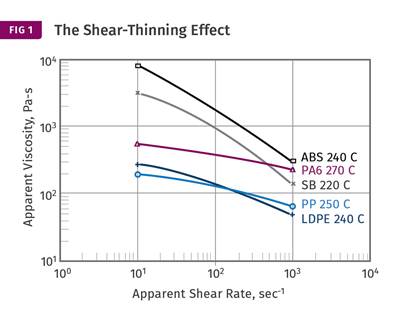

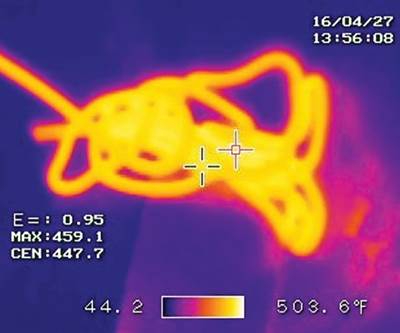

Read MoreUnraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

Read MoreFinding Root Causes of a Material Problem

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read MoreHow to Use Kinetic Modeling Analysis To Predict Profile Part Failure

Real-world project demonstrates how kinetic modeling can help estimate the shelf life of parts.

Read MoreNew Culture, New Capabilities, New Challenges

Over the last few years, Henkel has not only transformed what its Richmond facility does, but also altered how it operates in terms of culture.

Read MoreTwo-Shot Molding and Tool Design

There are a few variations of the two-shot molding process, and each has implications for tool design.

Read More