best practices

TOOLING: Let’s Get Serious About Mold Cooling: Part 2

Some creative thinking with conventional technology, like small cooling lines and bubblers, can generate big improvements in cooling and cycle times.

Read MoreINJECTION MOLDING: Purging: A to Z

Use these steps as a guide to minimize the time and money it takes to switch materials and color on your presses.

Read MoreAvoid Scale Buildup: The Silent Enemy of Cooling Performance

Obstructions in cooling can wreak havoc on molding. Here, a well-known supplier to molders that also molds recounts its experience and offers tips on how you can keep things flowing.

Read MoreTake a Systematic Approach to Keep Your Blenders Running Right

Increase uptime, productivity, and quality by putting together a comprehensive maintenance program to keep your blenders on target.

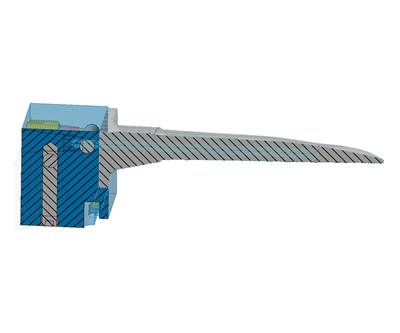

Read MoreTOOLING: Let’s Get Serious About Mold Cooling

Cooling is crucial to the molding process yet frequently overlooked. Here are some insights to consider.

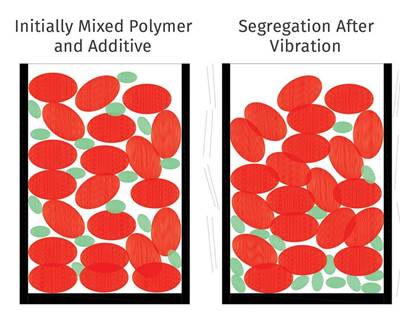

Read MoreEXTRUSION: Better Mix In Means Better Mix Out

Segregation or de-mixing of polymers and additives can be a big problem in single-screw extrusion. Here’s why it happens, and how to fix it.

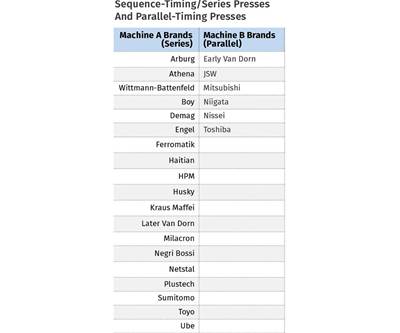

Read MoreINJECTION MOLDING: How Different Machine Types Handle Fill and Pack/Hold Times

The procedures are different between series and parallel machines. What type do you have? How can you tell? Here’s what you need to know.

Read MoreBlow Molding Challenges Embraced at Metro Mold

“Others mold difficult parts. We mold the impossible.”

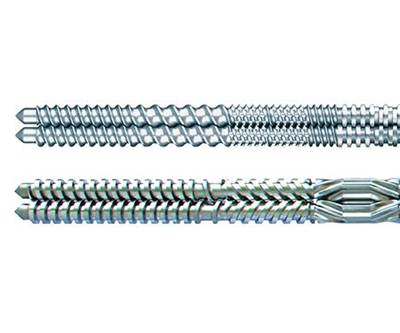

Read MoreGet Better at Swapping Out Your Twin-Screw Elements

Here’s what you need to know to safely and efficiently remove, clean, restage, and reinstall your twin-screw extruder screw set.

Read MoreTOOLING: The Tool’s Impact On the Molding Process

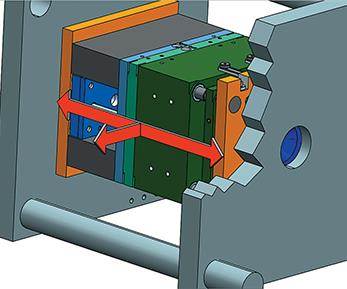

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

Read More