best practices

Compounder Finds Niche in Recycling

Combining compounding and recycling in one step is helping take Buckeye Polymers to the next level.

Read MoreMES Helps Molder Tackle Plant Efficiency

New central computer system dramatically improved operating efficiencies and slashed costs for a molder of tackle boxes and other types of cases.

Read MoreTOOLING: Repairing Molds in the Press: Part 3

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

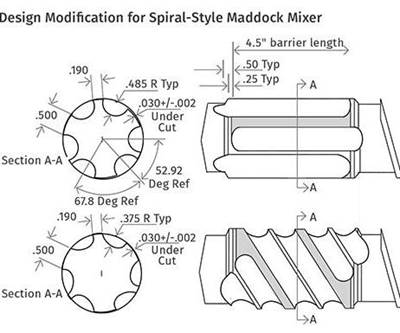

Read MoreEXTRUSION: Venerable Maddock Mixer Still an Extrusion Workhorse

Variations to this decades-old mixing section are widely used, but processors should carefully analyze these designs and not assume they will perform better.

Read MoreINJECTION MOLDING: Improving Barrel-Temperature Measurement and Control

Proper thermocouple placement and contact area are crucial, as is wire maintenance. But remember that barrel temperature and melt temperature are not the same

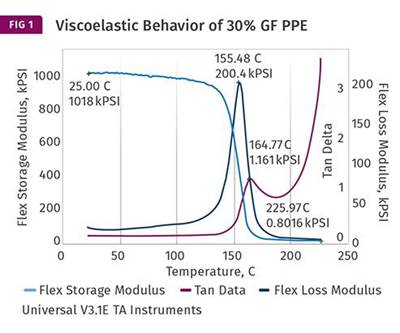

Read MoreMATERIALS: The Problems with Single-Point Data: Part 9

Time—and not just temperature—governs the behavior of materials under load. Both must be considered when evaluating a polymer for an application.

Read MorePrototype to Production: NPI/Medical Is Quick-Turn Artist

New name, same focus: From 1 part to millions, a new-product development manufacturer for over 45 years.

Read MoreMolder Builds a Business From Next to Nothing

Under new ownership, Cumberland Plastics Solutions’ decision to invest when times were tough has paid big dividends.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read MoreEXTRUSION: Managing Regrind

Reusing scrap is a necessary evil. But be aware of the negative impact scrap has on properties and extrusion efficiencies. Start by developing a regrind-usage program.

Read More