best practices

Solve Venting Problems on Twin-Screw Compounding Extruders

Compounds must be free of voids and volatiles or else the material will cause subsequent processing problems. Here’s how to ensure your venting is effective.

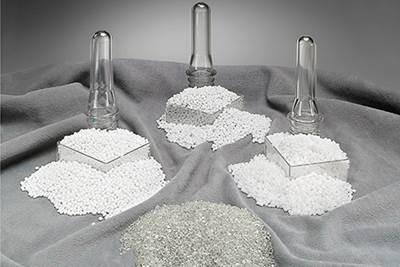

Read MoreWhy & When Should You Re-Crystallize PET Scrap?

Whether you’re blow molding PET bottles or extruding APET sheet, you’ll produce amorphous scrap in the process. How you handle it will impact your production costs. Re-crystallizing it will help.

Read MoreFor This Molder, Less Paper + More Data=Higher Productivity

At Tessy Plastics, going paperless means more than idle printers and fewer orders for three-ring binders.

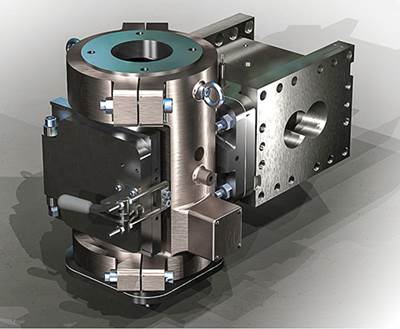

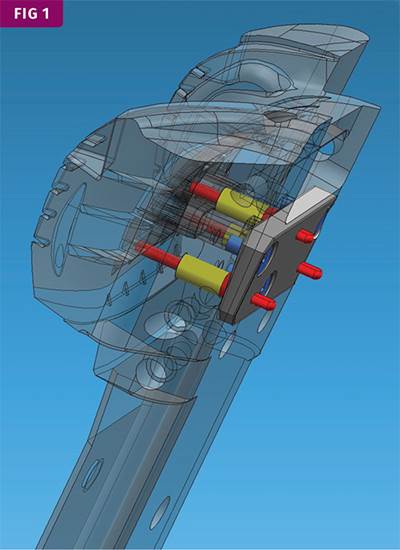

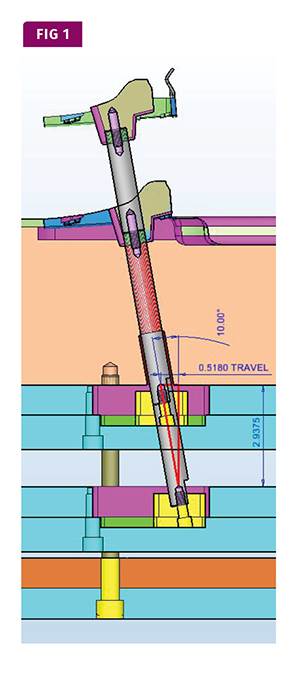

Read MoreTOOLING: Dealing with Lifters--Part 2

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

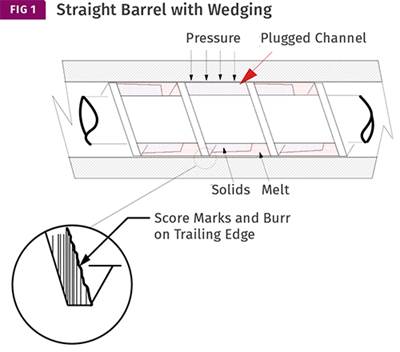

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

Read MoreINJECTION MOLDING: Gate-Seal Testing Done Right

Follow these 16 steps to perform the experiment and learn what is best for your part and process.

Read MoreSpeed to Market: Pretium Stays Light on Its Feet And Ahead of the Pack

A visit to its largest PET plant illustrates how this versatile blow molder leverages design skills, a can-do attitude, and a high degree of production flexibility to supply custom products in ever-shorter time windows. A new thrust into automation will help pick up the pace.

Read MoreAchieving Zero Waste: Two Processors Prove It’s Possible

Working with an Ohio-based recycler, two film and sheet processors go landfill-free.

Read MoreTOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Read MoreWhat You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read More