best practices

MATERIALS:The Problems with Single-Point Data

This real-world scenario explains why molders and their customers need to ‘think in terms of graphs’ and gather as much data as possible before selecting a material for an application. Part 11.

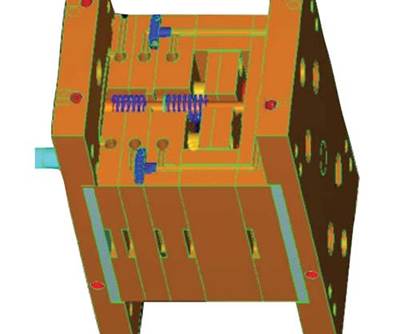

Read MoreINJECTION MOLDING: Properly Placing & Cooling Insulator Plates

Thermal-energy management from the mold to the platens is critical for making consistent parts.

Read MoreA Service Engineer’s Guide to Boosting Molding Machine Productivity

Consider these tips from a technician who’s visited about 4000 plants over a 40-year span.

Read MoreIntegrated Process Cooling Boosts Output, Cuts Costs

Closed-loop system helps an extrusion processor maintain quality of reusable straws and other products.

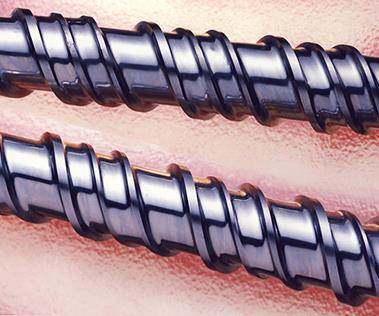

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

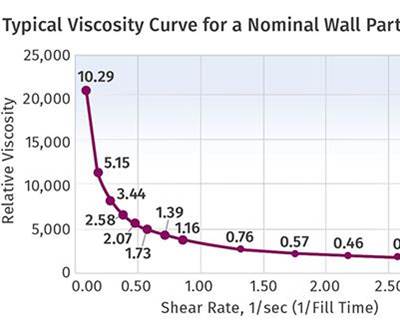

Read MoreINJECTION MOLDING: Do You Need to Profile Injection Velocity?

Look at the parts. If the answer is yes, the on-machine viscosity curve can help.

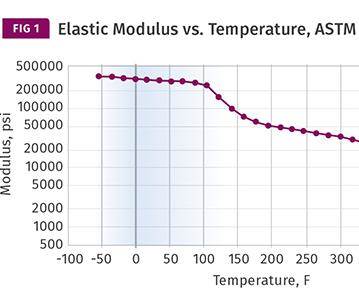

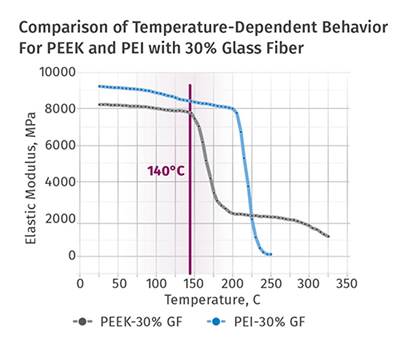

Read MoreMATERIALS: The Problems with Single-Point Data: Part 10

You can predict creep performance of a material over time at a particular temperature by examining how its modulus changes over a range of temperatures.

Read MoreTry a ‘Complete’ Method to Clean Screws, Barrels

Pulling the screw will give you direct access to clean all surfaces. Here’s how to do so in an efficient, safe, and non-destructive way.

Read MoreA Film Processor’s Guide to Understanding Materials & Equipment

Process engineers need to have a fundamental understanding of three areas: the material properties, the basic design parameters of the extrusion equipment, and the process window of the equipment.

Read MoreAdd Some Science To Your Purging Practices

Applying scientific methodology to purging techniques is safer and more beneficial than operating ‘on-the-fly’ or using home-made remedies.

Read More